Where have all the “leakers” gone?

By Ward Atkinson, MACS Technical Advisor

It has been said that back in the days of R-12, A/C system engineers sometimes used “Band Aid” fixes to address A/C system issues.

Speaking as one of those early engineers, there is some truth in that. System refrigerant charges then were very large compared to those today. Those systems were expected to leak refrigerant and still continue to provide cooling for an acceptable interval before more refrigerant had to be added.

Of course, all that was back before environmental threats became recognized and the role of refrigerants such as R-12 were linked to ozone depletion and R-134a to global warming.

History of 2003 Chevrolet Impala

Build Date: 10/2002

R-134a System Original Factory Charge: 992 grams (35 oz.)

First Service 2009 at 6-3/4 Years (Poor Cooling): Recovered 454 grams (16 oz.)

System Emissions at 6-3/4 Years: 79 g/yr. (2.8 oz.)

Second Service 2012 (Hose Leak): No Refrigerant Recovered

Lifetime 9-3/4 Years Refrigerant Total Loss: 1530 grams (54 oz.); 157 g/yr. (5.5 oz.)

All that changed with the transition from R-12 to R-134a. OE engineers and their Tier One suppliers revisited system and component designs, which resulted in mobile A/C systems that leak much less refrigerant and last much longer before any component failures.

Anecdotal evidence of improvements in system design to reduce refrigerant leakage is demonstrated through two vehicles operating in the Phoenix, AZ, area and which were serviced at the Car Repair Company.

One major initiative that contributed to these improvements was the I-MAC (Improved Mobile Air Conditioning) Program, which was facilitated through an SAE International Cooperative Research Program (CRP). The program was funded by government and industry.

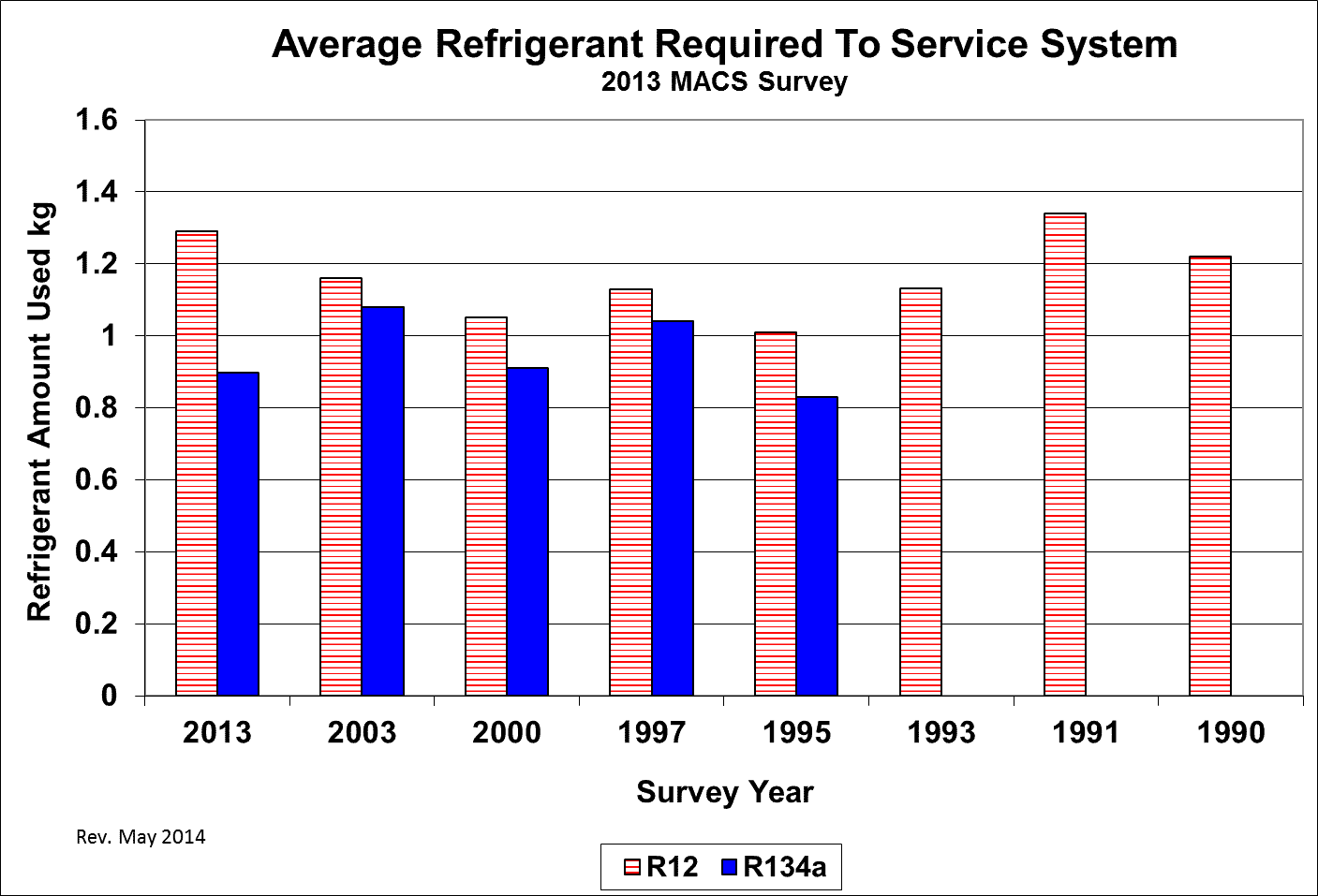

One of the I-MAC goals was to reduce refrigerant system emissions. Reducing the system charge will result in lower emissions when the complete charge is lost due to system damage or failure of component parts. The data in this figure compares system charge amounts from 1990 to 2013. Some of the typical R-134a refrigerant charge amounts for 2015 systems range from 0.36Kg (12.69 oz.) to 0.7Kg (24.69 oz.) for single evaporator systems.

MACS was specifically tasked to address service equipment that reduces refrigerant emissions during service and repair of mobile A/C systems. This included the improvement of refrigerant recovery, recycling and charging equipment for removal of refrigerant from the A/C system at the time of service, and provided more accurate refrigerant charge amounts. Another part of that work was to promote improvement of electronic leak detectors, which enabled technicians to identify smaller leaks in the A/C system. Additionally, MACS provided research, outreach and education designed to reduce refrigerant emissions through proper recovery when vehicles are scrapped.

The work to improve mobile A/C systems, components, service equipment and new mobile A/C systems continues under the stewardship of SAE International’s Interior Climate Control Standards Committee.

As mobile A/C systems have continued to evolve, the focus for A/C service shops has changed substantially. Back in the day, it was all about the A/C refrigerant circuit and components. Now, not so much.

Improper service by either unprofessional service shops or do-it-your-selfers with quick-fix interventions using something in a can may still foul up the A/C system refrigerant circuit. The manufacturers and sellers of A/C compressors have plenty to say about this.

Today’s focus for service shops is much more about electronic controls, and the ever-growing number of on board vehicle computers, which all have some say as to whether the vehicle A/C can operate (or not).

Our little corner of the automotive world continues to evolve but unfortunately, things are getting no easier for the service techs that have to troubleshoot and repair the A/C system.

If you’re a service professional and not a MACS member yet, you should be!

Become a member and receive a monthly technical newsletter with information like what you’ve just read in this blog post visit http://bit.ly/10zvMYg for more information.

You can E-mail us at macsworldwide@macsw.org .

To locate a Mobile Air Conditioning Society member repair shop in your area.

Click here to find out more about your car’s mobile A/C and engine cooling system.

Mobile A/C professionals should plan to attend MACS 2017 Training Event and Trade Show, February 15-18 at the Anaheim Marriott in Anaheim, CA.

Click here to see MACS current public training schedule.

The MACS website is located at www.macsw.org