Heavy duty truck and off-road training digest

By Dr. Alex Moultanovsky

The MACS session began with Dan Spurgeon of CAT who introduced the new Track-Type Tractor D6. Dan pointed out that the D6 is equipped with a completely new design HVAC system called Conditioner Group, which is mounted outside the cab. This Group is a combined heat and A/C system built as a compact, low profile box, with improved reliability, high performance, reduced service time and optimized to meet A/C, heating, defrosting and sound level targets. Condenser group, part of Conditioner Group, is easily removable (when required) as a single unit. Mr. Spurgeon explained that condenser fans are reversible and they, as well as the blower, are brushless. Speed of fans is adjustable based on ambient and heat load.

Next, the speaker presented the 120 Motor Grader. Its Conditioner Group is also mounted outside on the back of the cab (in the previous version the system was located under seat). Benefits of this group are very similar to the D6 machine group. However, he noted that the motor grader’s air ducting system, which is very complicated, provides excellent air distribution to the cab. These two, as well as most other CAT HVAC systems, have common software, and typically for such control systems in different machines, are very similar. They can control everything: blower speed, fans, compressor, condenser fans, variety of sensors, etc.

The second part of the CAT presentation was on selection of an alternate refrigerant for off-highway machines. Spurgeon pointed out that the Paris climate agreement (specifically for R-1234yf refrigerant) was adopted by EU and 120 other countries, including the U.S., Canada and Australia. He advised the audience that CAT completed the R-1234yf technical and manufacturing solution; system design is in process and the dealer network isn’t started yet. He concluded that new CAT R-1234yf machines will be available within the near future.

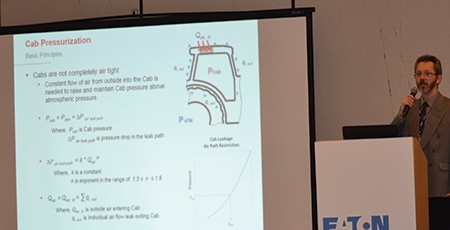

Leo Chernyavsky of CNH covered cab pressurization and CNH machine service updates. Most of CNH equipment operates in a very dusty environment, indicating that very important issues are cab sealing, air filtration and cab pressurization. Leo pointed out that the operator’s comfort zone lies between 50pa and 200pa with fresh air about 43m3/hr. Pressurization requires appropriate cab sealing and fresh air delivery, as well as a pressure relief method and control method. He said that the cab leakage curve always must be between min/max acceptable cabin pressure.