VOCs and the ‘new car smell’

By Aaron Canada, Engineering Coordinator, Keihin North America Inc.

Many people say they love the smell of a new car. Buying one can be very exciting for multiple reasons. For some, it is the excitement of advanced technology or the latest functions that come with a fresh, shiny automobile. For others, it is achieving a personal milestone and improving their quality of life. With these reasons and others, the new car smell triggers joy in many people. To extend the duration of joy, air fresheners can be purchased with a ‘new car’ scent to bring the euphoria back to cars that are beginning to show their age.

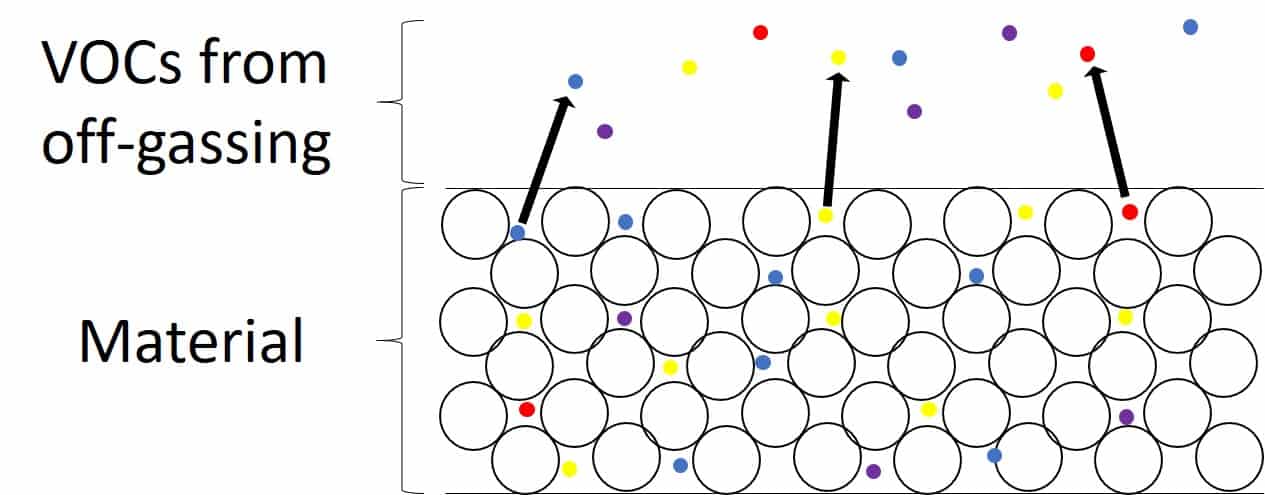

Figure 1: VOCs vaporizing from a material into air

The new car smell is caused by several interior components that release Volatile Organic Compounds (VOCs) from off-gassing after they are manufactured. Off-gassing continues after the interior components are assembled into a vehicle, and then the beloved new car smell develops. In addition to odor, another result of materials off-gassing is fogging. Fogging is the film that can develop on windows and impede the driver’s visibility through the windshield. The effect of fogging is no wanted, but the odor created from components is desired by some. The new car smell fades over time after the majority of VOCs have vaporized and are released into the environment when the windows and doors are opened. The image in Figure 1 intends to represent the process of off-gassing with VOCs becoming airborne after being vaporized from a material.

Now that we know the new car smell is from VOCs, it is important to understand the impact of VOCs on consumers. The overall health impact may be unknown, but it is reasonably clear that there are no health benefits from VOC exposure. Reports indicate that some people experience “Sick house syndrome”, nausea, or fatigue from exposure to VOCs. Some VOCs may even cause cancer with a high exposure concentration. One of the VOCs with the most awareness is formaldehyde. While formaldehyde is known to preserve biological tissue and is contained in many household furniture products, formaldehyde is also found in many automotive components (at a much lower concentration than you will find in a biology lab).

The Environmental Protection Agency’s (EPA) Federal 40 CFR 59 and California Air Resource Board’s (CARB) Article 2 currently regulate some VOCs for building materials and consumer products, but VOCs in automotive interior cabins are not regulated in the U.S. As the public becomes aware of Indoor Air Quality (IAQ) and the impact of VOCs, governments and the automotive industry are working to reduce the exposure of VOCs to vehicle occupants. Currently, China, Japan and South Korea regulate VOCs in automotive interior cabins. Most OEMs have global footprints; manufacturers of vehicles sold in the U.S also have strived to monitor and reduce VOCs as a result of the components used in the U.S, which may be sold in one of the aforementioned countries.

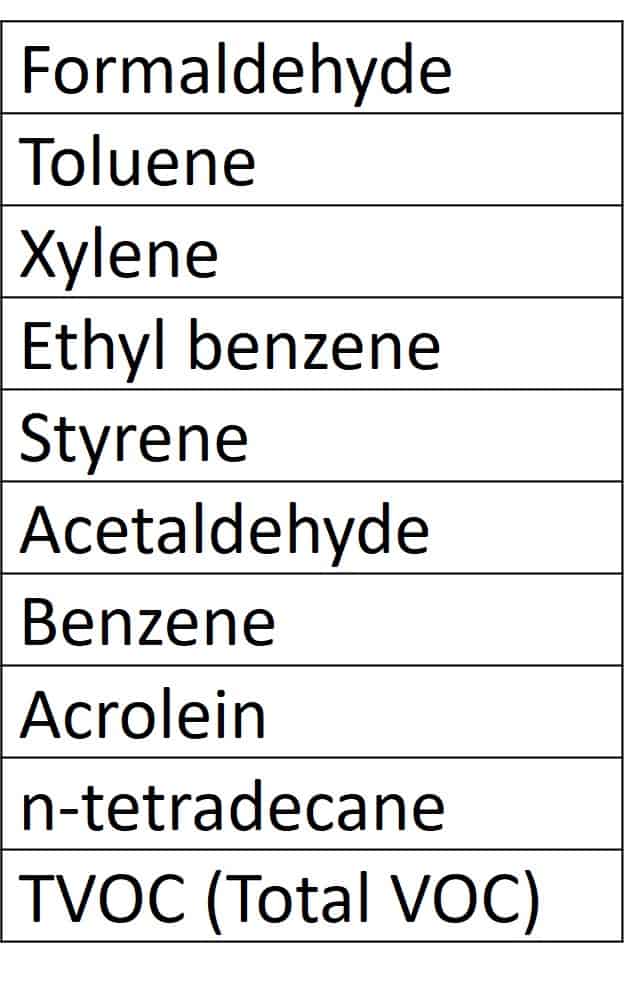

Figure 2 lists the VOCs that are typically measured in automotive components, but this varies by country. Total VOC (TVOC) includes the VOCs listed in addition to other VOCs that are contained in the item being measured.

Managing VOCs can be a challenge for OEMs, since the VOC content of the interior cabin is composed from several parts made by multiple suppliers. Therefore, the OEM must create a limit for each supplier and forecast the overall VOC content for the interior cabin.

Figure 2: List of VOCs that are typically measured

The VOC content of individual components is measured by placing the component in a bag that is sealed and sent to a test facility. VOC testing, which is performed only at qualified test labs, takes specialized equipment and expertise. Once the bagged part arrives at the test facility, the part is placed in a chamber for measurement. Measurements are typically collected at elevated temperatures to accelerate the release of VOCs. The VOC contained air from the part being measured is pumped through sorbent tubes that capture the VOC molecules. The VOCs in the sorbent tubes are then quantified with gas chromatographs and mass spectrometers, enabling the manufacturer to determine the mass of VOCs in the part tested.

Overall VOC content in automotive interior cabins is measured in a whole vehicle test chamber, and the interior cabin is isolated by having the windows and doors closed. After the correct conditions are met, air is collected from the interior to determine the concentration of VOCs. The International Organization for Standardization (ISO) has developed multiple types of measurement methods to simulate ambient, parking and driving modes. Several countries and organizations have test methods, but ISO 12219-1:2012 is the industry’s attempt to standardize the method to quantify VOCs in automotive interior cabins.

Are there any drawbacks to using low VOC materials? Some materials are known to have high levels of VOCs, but they may have excellent physical properties. This is where challenges arise for automotive engineers. Materials with low VOCs may have inferior properties, or comparable substitutes may have a higher cost. While the industry tries to lower VOCs in the interior cabin, it may be difficult to sell a vehicle for a higher price because of a low-VOC interior. However, you can easily find low-VOC paint with a higher price in hardware stores. We have all seen the sticker that states “Ice Cold A/C” on used cars, so can you imagine a “Low-VOC Interior” sticker on cars at a dealership?

Fortunately, material science has advanced. Thus, components with fewer VOCs can be made with a similar performance and cost. Materials such as plastics and adhesives have had a positive trend with VOC reduction over the past 10 to 20 years. Although progress has been made, many companies are still looking for ways to further reduce VOCs in their products for better consumer benefits.

How does this information relate to you? I hope you can help educate consumers about indoor air quality, and can appreciate one more item related to the development of automobiles. The journey to reduce VOCs will continue, and several organizations are working towards this goal. If your customers get excited about indoor air quality, you might be able to sell more cabin-air filters. If a customer complains about poor visibility, make sure their windshield is clean and explain the impact of VOCs and fogging.

The next time you hear someone state that they love the ‘new car smell’, you will be able to talk to them about formaldehyde, toluene, and other VOCs.