The concept of superheat

By Richard Hawkins, MACS Contributor

We illustrated the concept of superheat in last week’s article by boiling water and superheating steam in a moonshine still.

This week we will apply this concept to refrigerant in an air conditioning system. The still has been replaced with an evaporator. The heat source (the fire and propane torches) has been replaced with 80° F air being blown through an evaporator. Lastly, we will replace the water with R-134a refrigerant. At atmosphere pressure, R-134a boils at -15.3° F (15.3° below zero). At 30.4 PSI, R-134a boils at 35° F. Please see picture #1.

Picture #1: An evaporator surrounded by 80° F air.

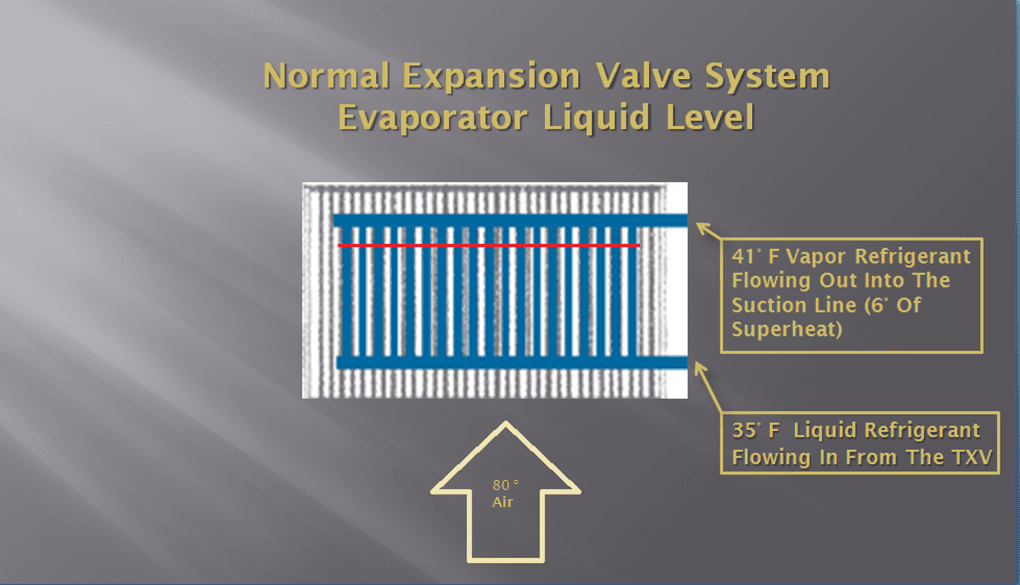

In an expansion valve system, the expansion valve controls the liquid level in the evaporator. This prevents liquid from flowing to the compressor and damaging it. The superheat setting of the expansion valve is what determines the liquid level. Use of an expansion valve with a low superheat setting (2° F for example) will result in a higher liquid level than one with a higher superheat setting (8° F for example).

In a properly charged, properly functioning expansion system; the liquid level in the evaporator is probably somewhere around 80%. Please see picture #2.

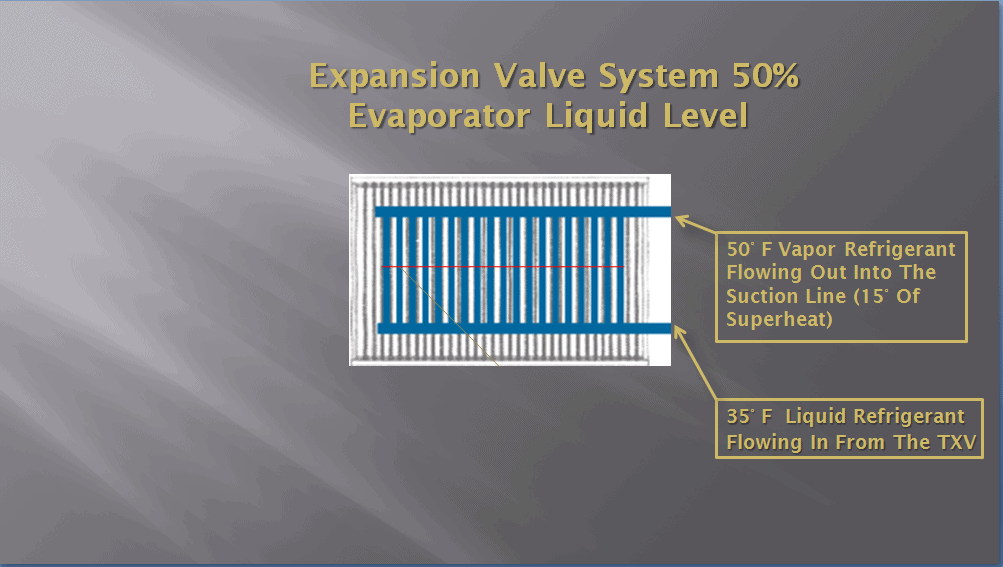

If the liquid level is lowered, the result will be increased superheat. Please see picture #3.

Picture #3: With the liquid level down to about 50%, there is a significant increase in superheat (from 6° F to 15° F.)

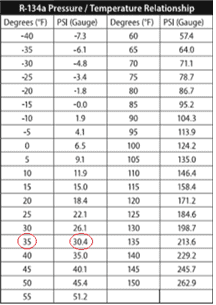

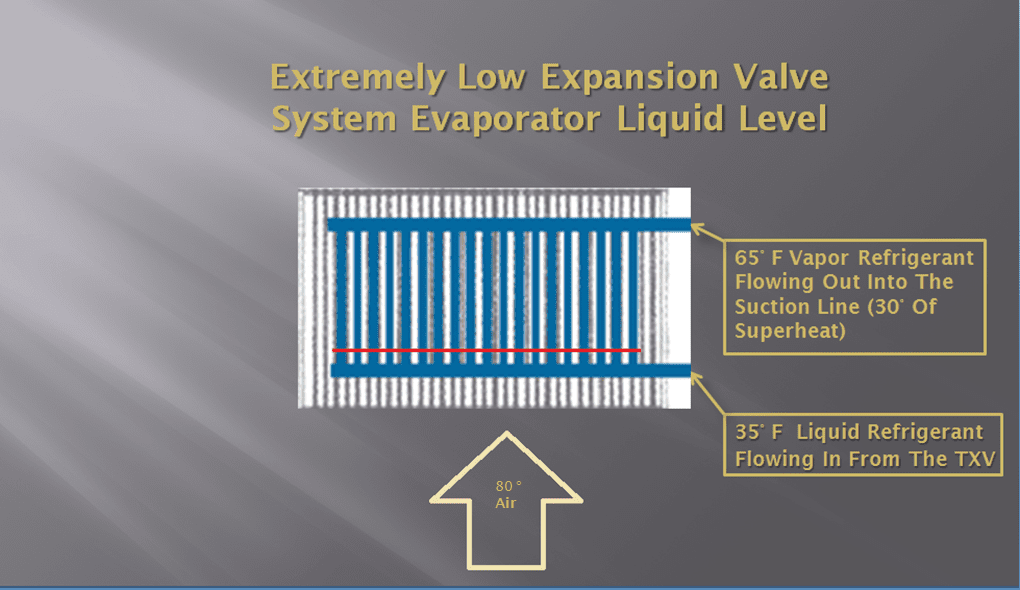

If the liquid level is lowered further, the result will be even more superheat. In the case study we began this series of articles with on October 5th, the low side pressure was at from 30 to 32 PSI and the suction line temperature was 65°F. Looking at a PT chart, that indicates about 30° F of superheat. Please see picture #4.

Picture #4: An R-134a PT chart. Notice the temperature of the refrigerant in the 30 to 32 PSI range.

The refrigerant entering the evaporator from the expansion valve was about 35° F and there was a low liquid level because the expansion valve was restricted. The restricted expansion valve also resulted in a lower-than-normal refrigerant flow. As it absorbed heat, the refrigerant boiled.

The vaporized refrigerant made its way on through the evaporator, which was exposed to 80° F air. During this journey it absorbed enough additional heat to become superheated to 65° F. So, that is why the suction line temperature was at 65° F with a low side pressure of 30 to 32 PSI. Please see picture #5.

Picture #5: The combination of a low refrigerant level, low refrigerant flow and 80° F air being blow through the evaporator is what caused the temperature of the suction line to be 65° F.

Would you like to join MACS as a member and have access to more mobile A/C technical information? Click on the QR code to become a member today.

Leave a Reply