The effects of air contamination in an A/C system

By Richard Hawkins, MACS contributor

If you perform an Internet search for effects of air contaminated refrigerant on automotive A/C system pressures, you’ll find many results. This information leaves no doubt that air contamination of refrigerant in an automotive A/C system can affect system pressures and temperatures.

However, there doesn’t seem to be anything about specific levels of contamination and their effect on system pressures and temperatures. To fill something of a void and provide some useful information, we did some testing. There were three tests run.

The subject vehicle was a 2011 Ford Crown Victoria with a fixed displacement compressor and a cycling orifice tube system with a 27 oz. refrigerant capacity. The first step in this test was to check the refrigerant with a refrigerant identifier to be sure there was no contamination. Then the system was run until it stabilized. Next, the following information was recorded: Ambient temperature, system pressures, evaporator inlet and outlet temperatures, condenser inlet and outlet temperatures and vent temperature.

These tests were conducted with the engine running at a curb idle, ambient temperature in a range of about 69° to 73° F, high blower speed and the system running on the outside air mode. It was set on high blower speed and outside air to increase the heat load and prevent system cycling. This was necessary because of the mild ambient temperature. As a result, the vent temperature was higher than what it would have been with the system running at a lower blower speed and in the recirculation mode.

That information is as follows:

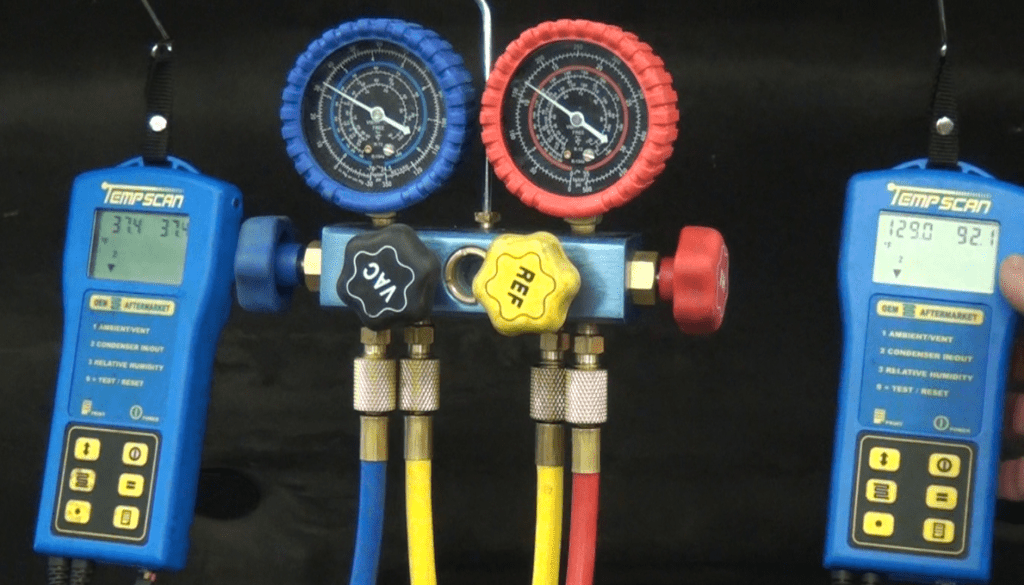

Test #1 with 0% air contamination.

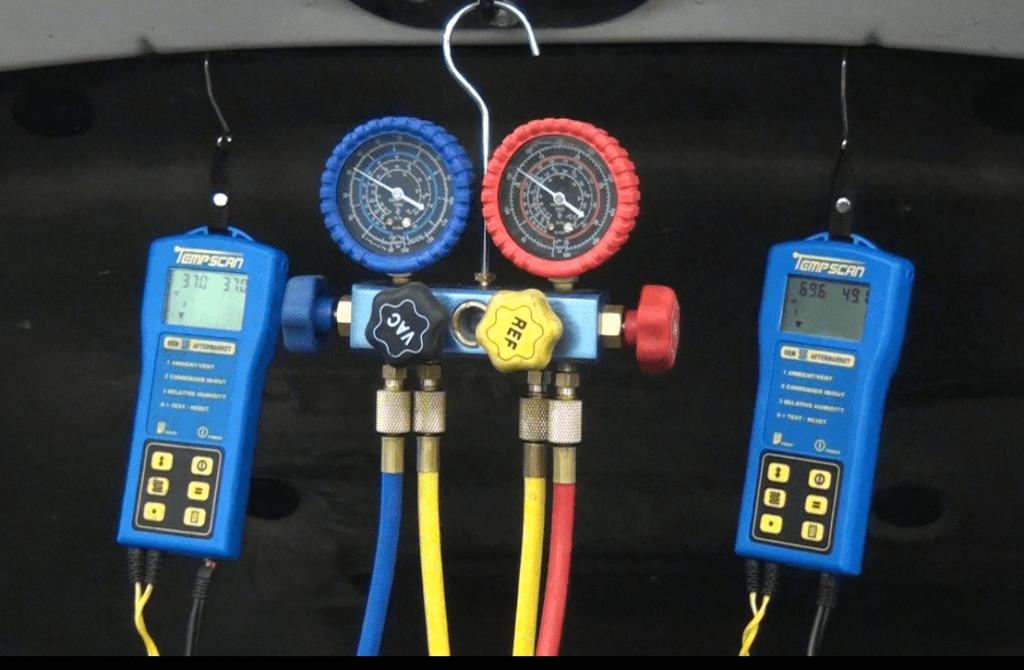

Ambient temperature: 69.6° F

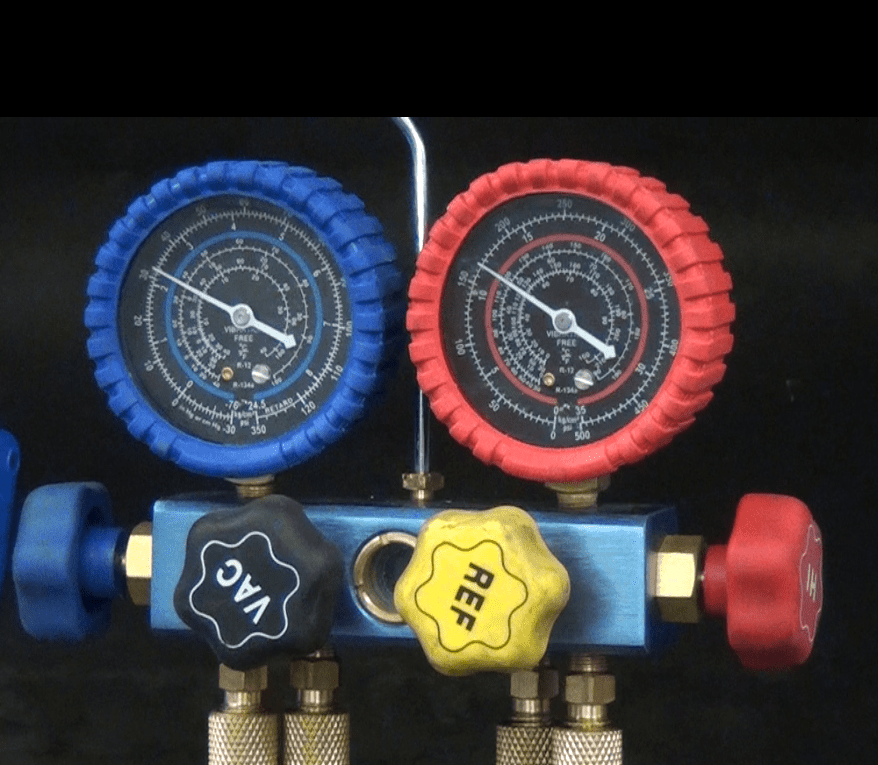

High side pressure: 165 PSI

Low Side pressure: 32 PSI

Evaporator inlet temperature: 37.4° F

Evaporator outlet temperature: 37.4° F

Differential: 0° F

Condenser inlet temperature: 129.0° F

Condenser outlet temperature: 92.1° F

Differential: 36.9° F

Vent Temperature: 49.1° F

Please see pictures #1, #2, #3 and #4 below.

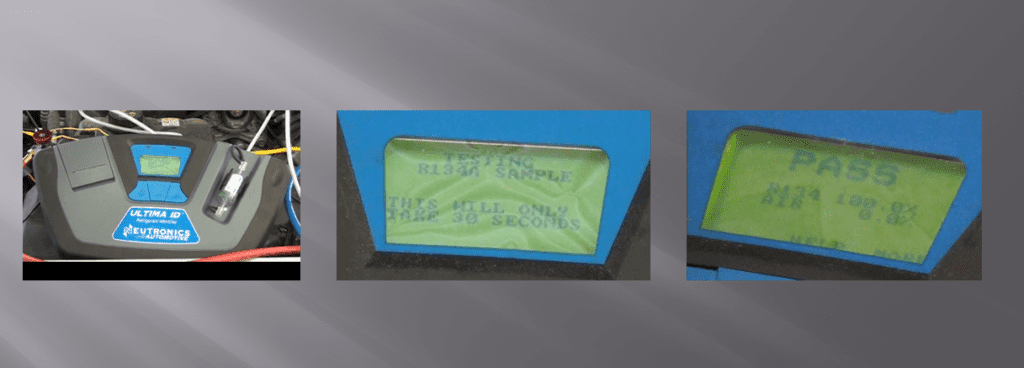

Picture #1: Testing the refrigerant for the presence of air. As the display indicates, there was no air present.

Picture #2: The equipment setup for the tests. The Tempscan on the left is reading the evaporator inlet and outlet temperatures. The gauge set of course is reading the system pressures. The Tempscan on the right is reading the condenser inlet and outlet temperatures.

Picture #3: A close-up of the system pressure readings.

Picture #4: The Tempscan on the right has been switched to read the ambient temperature on the left-hand side of the display and the vent temperature on the right-hand side of the display.

After completing test #1, the next test was to intentionally contaminate the system with some air. This was done with a blow gun injecting air through a service port. We used shop air that was run through a dryer so moisture would not be introduced into the system. The aim was for about 8% to 10% and when checked with a refrigerant identifier, the air contamination level was at 7.7%. We then ran the system and recorded the same pressure and temperature information recorded in test #1.

The next test involved increasing the air contamination level further. We were aiming for about 20% and the refrigerant identifier indicated it was at 18.9%. The system was run, and the pressure and temperature information were recorded with this contamination level.

Check back in next week and the results of tests #2 and #3 will be provided.

If anyone would like to venture some guesses on any of the pressures and temperatures, we invite your input. This can be done in the “Leave a Reply” area directly below.

Join MACS as a member to have access to more great technical information.

Leave a Reply