Compressor oil and the drain plug

By Richard Hawkins, MACS contributor

Questions about compressor lubrication are frequently encountered on A/C tech lines. These questions can lead to some interesting conversations. Based on my own personal experience and an informal poll of tech line representatives, there are many compressor installations done where proper compressor oiling procedures are not being followed. Let’s discuss compressor oil and drain plugs.

When draining oil from compressors which have drain plugs, proper draining procedures call for the removal of the drain plugs and the unit drained from both the drain plug hole and the suction and discharge ports. When installing oil in these same compressors, the oil should be installed through the drain plug hole. When having a conversation on a tech line about compressor lubrication, a sizable percentage of technicians do not seem to be aware. Please refer to picture #1.

Picture #1: These compressors all utilize drain plugs.

This can easily result in the wrong amount of oil in a system, depending on the circumstances: For example, a shop might be working on a vehicle which has an A/C system with a 4 oz. oil capacity. The system has suffered a catastrophic compressor failure. The condenser (which contains a drier) is being replaced and the remainder of the system is flushed.

As a result, this is a dry system which needs 4 oz. of oil. The vehicle uses a variable displacement compressor which has an oil drain plug (as most variable displacement compressors do). The technician drains the replacement compressor from the suction and discharge ports and a total of 1 oz. of oil comes out.

Satisfied that all of the oil has been removed from the compressor, the tech installs 4 oz. into the suction port and reassembles the system. The problem is that the compressor contained 4 oz. of oil and because the unit was not drained from the drain plug hole, 3 oz. remained inside. With the addition of the 4 oz, the system will have a total of 7 oz. of oil in it. That is a 75% overcharge of oil, and the result will be poor system performance.

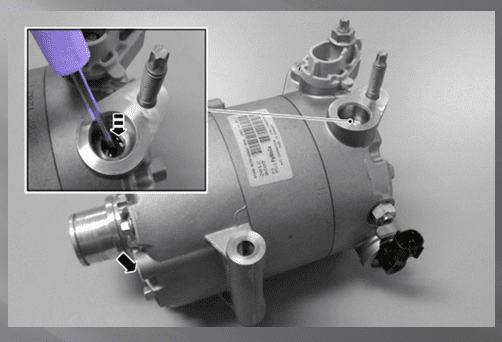

As indicated in the picture, most drain plugs are located on the side of the compressor case or in the case of the TSRE09, on a pedestal at the rear of the unit. However, there are some compressors which require that the clutch and field coil be removed in order to access the drain plug which is located on the front head. Please refer to pictures #2 and #3.

Picture #2: This Denso compressor requires removal of the clutch and clutch field coil to access the drain plug.

Picture #3: This same compressor requires the suction damper be depressed to allow for proper ventilation when draining.

While we are discussing compressor oil, here are a couple of other important things to remember:

- Some replacement compressors use a different viscosity oil than their OEM counterparts. This is because the replacement compressor might use a different internal design. Always use the viscosity of oil specified for the specific compressor being installed.

- R-1234yf systems call for special oils which contain special acid reducing additives. Generally, the yf oils are compatible with R-134a but the R-134a oils are not compatible with the R-1234yf,

Join MACS as a member for more mobile A/C technical information.