As the belt turns

By Steve Schaeber, MACS Technical Editor

Checking the Accessory Drive Belt System (ABDS) is one of the most basic preventative maintenance procedures we do as technicians. Most of the time, it only requires a quick look around at the belt, pulleys, idlers and components to see if everything’s OK. While we don’t often find major issues, sometimes a problem can get pretty severe before it actually causes a catastrophic failure. In fact, the vehicle operator may not notice any noises and everything may seem to be functioning correctly while major problems are lurking under the hood.

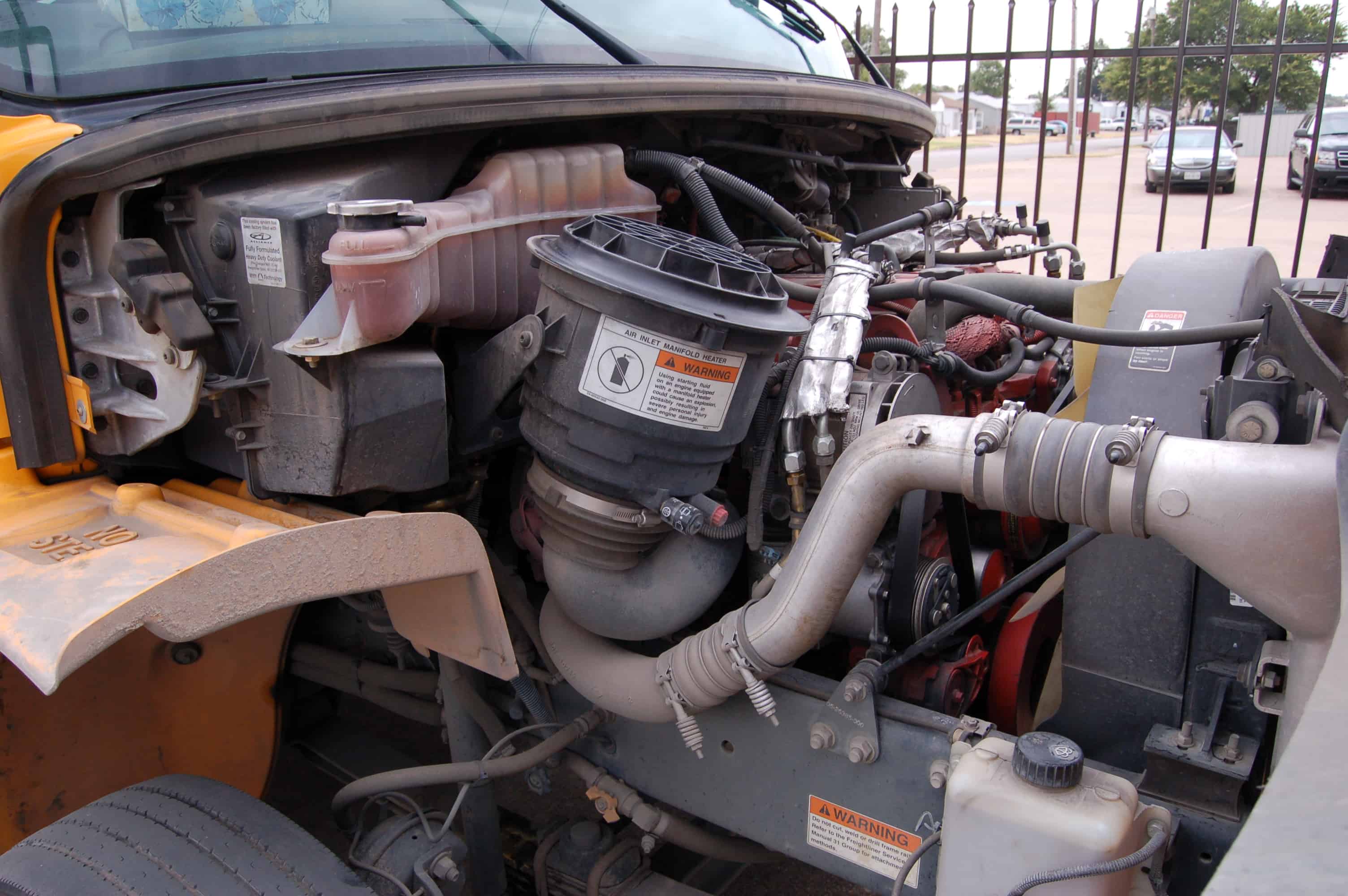

A/C is increasingly becoming more popular in many school buses, especially in southern states like Texas.

Here’s an example we found on a late model school bus. With only 68,000 miles on the odometer, the engine ran great as would be expected for a 2009 model year vehicle. When testing the A/C system, it quickly started blowing out air at 60°F, even though it was 105°F on a hot, dry Texas afternoon. Everything seemed to be fine, that is, until we opened up the hood.

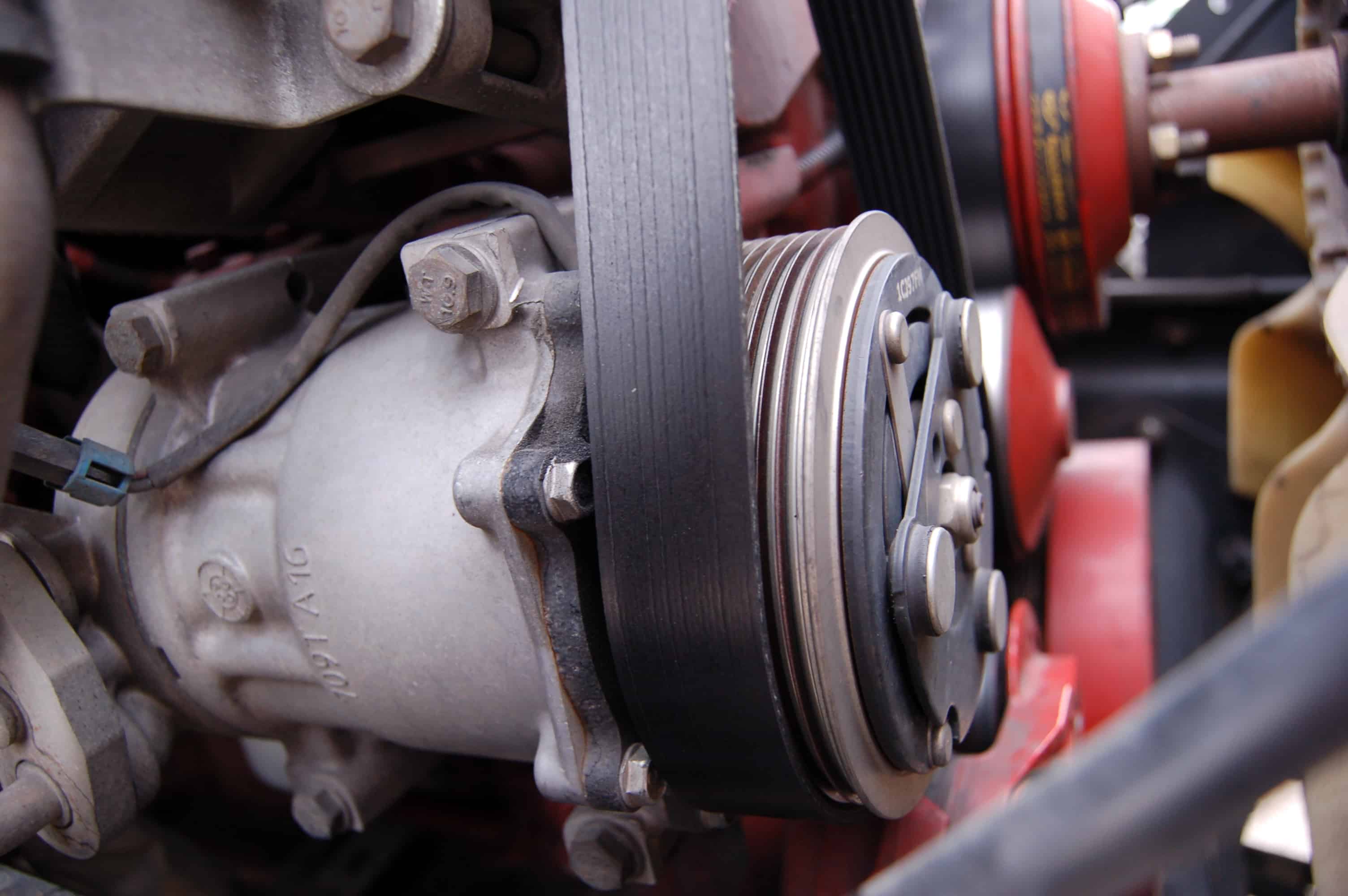

Closer inspection shows the A/C compressor drive belt is riding off track by two teeth, but that’s not all. The belt is actually rubbing up against the head of a bolt. As it wears, rubber material is grinding off and building up on top of the bolt.

As the tensioner wears on its pivot through normal operation, dark colored dust will build up on its body. The angle of the tensioner pulley becomes increasingly more crooked in relation to the compressor pulley, forcing the belt to ride slightly off track. If this condition is not corrected (likely by replacing the tensioner and installing a new belt), the belt will continue to wear and eventually fail. Not only would this disable the A/C compressor, it would also affect alternator operation, along with any other accessories driven by this belt.

Follow the trail; it will lead you to the culprit. In this case, it’s the belt tensioner that’s causing the problem.

Have you seen something that was just about to break, even though it still seemed to be working? Why not take a few pictures and share your story with MACS! Send an e-mail to steve@macsw.org or check out our website at www.macsw.org for more information!