Proper compressor draining and filling procedures

By Richard Hawkins, MACS Contributor

In the preceding blog articles, draining the oil from both the original and replacement compressor and filling the replacement unit has been mentioned a few times. This seems like a relatively simple process and it is with the compressor used on the 2002 Tahoe: You drain it from both the suction and discharge ports and most of the oil will be draining from the suction port. Then you install the oil in the suction port. A different procedure is required on a lot of other compressors and based on my tech line experience; a huge number of technicians are not aware of this.

The difference is that the compressors which require the different draining and filling procedure have a drain plug and to properly drain them, the drain plug must be removed. Then the unit must be drained from the drain plug hole, suction port, and discharge port and most of the oil will be draining from the drain plug hole. The fresh oil is then installed thru the drain plug hole. Not doing the procedure this way can result in both the possibility of not having enough oil in the system or having too much depending upon the circumstances. This is because with the oil not being drained from the drain plug hole, you are not getting it all out and you do not know how much oil was in the compressor. Also, filling a compressor with a drain plug through the suction port (instead of drain plug hole) results in the oil being introduced into the wrong area of the compressor which can cause issues and it may not be possible to get all the oil in through the suction port.

So that brings up two questions:

1. Why do some compressors have drain plugs while others do not? That is because of differences in internal designs.

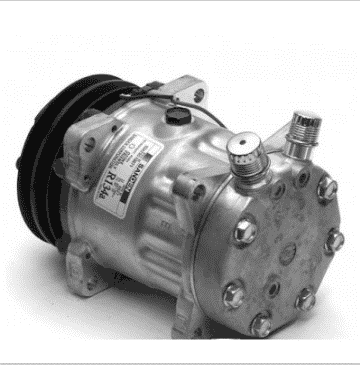

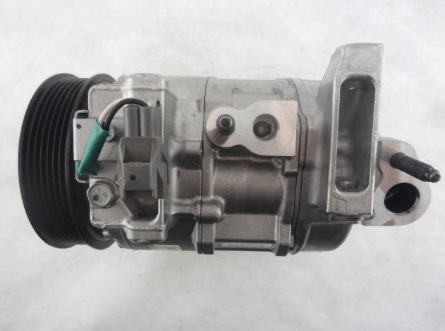

2. How do we know which compressors have drain plugs? That gets a bit involved because of all the different compressors that are in use, so we will focus on just belt driven compressors that are used for automotive and light truck applications (no electric, hydraulic driven or HD units). Most variable displacement compressors utilize drain plugs. Most fixed displacement compressors do not. The notable exception to that is Sanden as just about all Sanden compressors have drain plugs, regardless of type. Also, the older GM A-6, Chrysler RV-2, York, and Tecumseh fixed displacement compressors all had drain plugs.

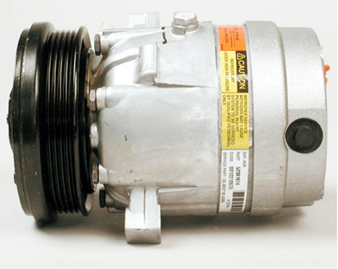

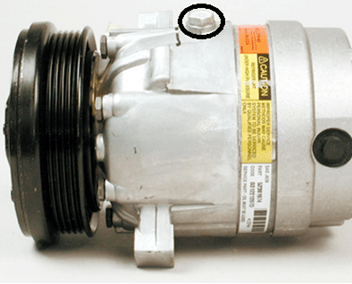

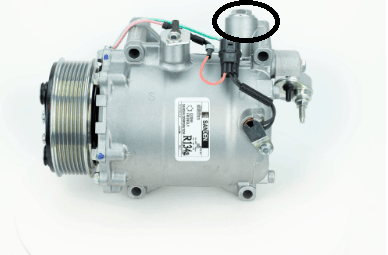

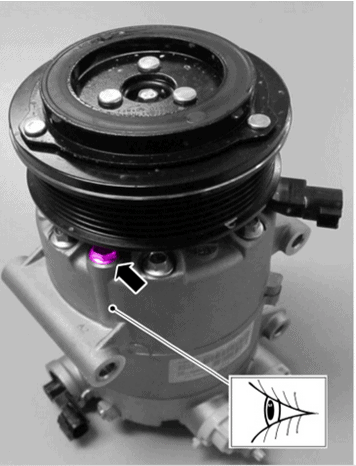

To be sure, it is necessary to look closely at the compressor, as it is easy to mistake a hi pressure relief valve or bolt heads that might be present for a drain plug. To assist you in the identification process, we have included pictures of several commonly encountered compressors which have drain plugs. Please refer to pictures 1 through 4. Picture 5 shows a Denso compressor that even requires clutch removal to access the drain plug. If in doubt, contact your supplier and they should be able to find out for you.

Below are photos detailing drain locations on various compressors

1- if pag oil is hygroscopic , then why its not popular practice to drain compressor with each repair if the procedure doesn’t exceed 10 minutes ?

2- how can i vacuum and dry total system oil without removing parts , is it by blowing nitrogen or feron , if so can you explain the steps ?