How much oil “goes” in the compressor?

By Richard Hawkins, MACS contributor

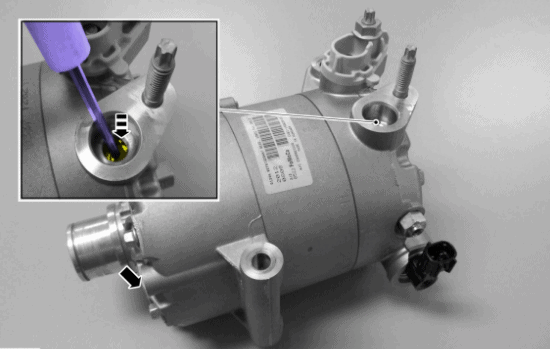

In the previous blog article, the last picture showed a Denso compressor which requires clutch removal to remove the oil drain plug. There is also an additional step which is required in the oil draining process with this unit. That step is that the suction damper needs to be depressed to allow proper ventilation when draining one of these compressors. Please see picture #1 below.

As mentioned previously, it is estimated that approximately 25% of A/C tech line calls involve questions pertaining to lubrication and the most frequently asked question seems to be: How much oil “goes” in the compressor?

That is a wide-open question that can have several different answers depending on the nature of the service work and a lot of inexperienced technicians tend to get frustrated because a quick answer just is not possible. So, let us take a look at the variables that are involved.

A. As outlined in the February 4th. article, if just the compressor is being replaced then an oil balance needs to be done with the net result being the same quantity of oil that was in the old compressor being installed in the new compressor. However, if only a small amount drains from the old compressor, then additional steps need to be taken to guard against compressor oil starvation, as outlined in the February 23rd. article.

B. If the system is “dry” due to flushing and component replacement, then the total system capacity is required, and oil balancing isn’t necessary. Sometimes that brings up an additional question such as what percentage of the total charge needs to go in the compressor? That question arises because as a system is run, the refrigerant carries oil to all the different components and it’s common to find component replacement capacities listed in service information. As a result, there are two different schools of thought on this: Some shops like to just install all the oil in the compressor as the OEMs do at the assembly plant, while others like to spread the oil through the system. Both procedures seem to work fine, but if spreading the oil through the system, care should be taken that no less than 50% of the oil goes in the compressor.

Also there is something else that needs to be taken into consideration that is important: If a system uses a compressor with an oil separator, as a lot of late model vehicles do, then all of the oil should go in the compressor. This is because the purpose of the oil separator is to keep most of the oil in the compressor to increase the efficiency of the evaporator and condenser as oil acts as something of a thermal blanket in those components.

To access more material like this Join MACS as a full member.

To contact the MACS staff call 215-631-7020 x 305, 311 or 313

Click here to send a message or ask a question.

Leave a Reply