What is your temperature testing data telling you?

By Richard Hawkins, MACS Contributor

If air conditioning systems were transparent where we could see inside them, then diagnostics would be faster and easier. We could look at the systems and see things right away that affect system operation, like restrictions and liquid levels in evaporators and condensers.

A/C shops don’t have X-ray machines or ultrasounds to examine their patients, but temperature testing can provide a means for visualizing some things that might be taking place in a system. The key to doing that is understanding what the temperature readings mean.

Here are some examples:

When temperature testing a receiver drier, the inlet and outlet temperature should be about the same. The reason is you have very warm (sometimes hot) refrigerant flowing in from the condenser traveling through some filtering media and desiccant and there is little resistance to flow.

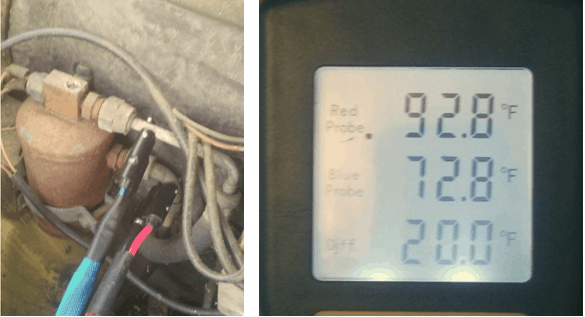

If you have temperature tested a receiver driver and the outlet was significantly lower, let’s say 20° less than the inlet, that indicates a restriction. See picture #1 below. The restriction would be creating a pressure drop and when refrigerant is flowing and encounters a pressure drop, the refrigerant temperature drops as well.

The greater the temperature drop, the greater the restriction, so a 60° temperature drop would represent a greater restriction than a 20° temperature drop. When applying this information there is one caveat to remember: A total restriction will result in no temperature drop. A total restriction is no different than having a valve in the system which is shut off. There must be some refrigerant flow for a temperature drop to take place.

Another example where temperature testing is often utilized is charging an orifice tube system. You connect to the inlet and outlet of the evaporator and observe the temperatures. If the outlet temperature is significantly warmer (let us say 20°) that could indicate a restricted orifice tube or a refrigerant undercharge. The next step would be to add an ounce or two of refrigerant and see what that did to the temperature differential. If the differential stayed the same, that would point toward a restricted orifice tube. If the temperature differential decreased (let us say from 20° down to 10°), that would indicate an undercharge condition. So, what is going on?

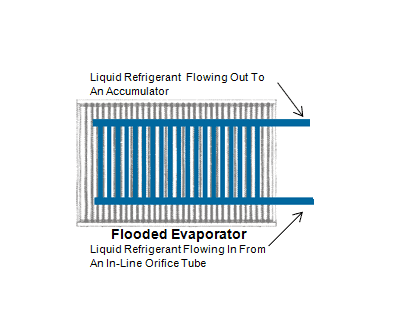

First, we need to understand that an orifice tube system is a “flooded evaporator system”. See picture #2 below.

(where it changes state to a vapor)

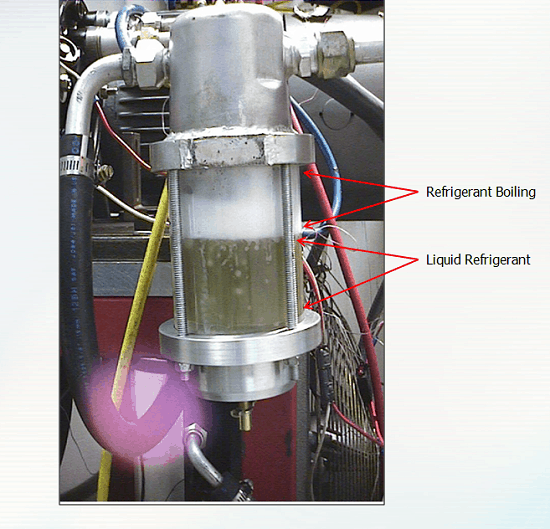

If the system is charged and operating properly, the evaporator will be full of liquid refrigerant and it will be flowing into the accumulator and the accumulator will have about a 40% to 50% liquid level in it. The refrigerant then changes state to a vapor (boils) in the accumulator. Please see picture #3 below. If there is a refrigerant undercharge or the orifice tube is restricted, the evaporator will not be properly flooded.

As a result, the refrigerant exiting it will be a vapor (instead of a liquid) and it will be superheated and the cause of the temperature difference.

Do you like our content? Join MACS today as a member and see how much more we have to offer.

Leave a Reply