Temperature testing detective work: The search for a diagnosis

By Richard Hawkins, MACS Contributor

Temperature testing to diagnose a mobile A/C repair, requires some detective work.

Last week we closed our blog post with a discussion about an orifice tube system. The evaporator outlet temperature was about 20° warmer than the inlet. We mentioned that this could be an indication of a restricted orifice tube or a refrigerant undercharge. In applying this to diagnostics, it is important not only to understand what this represents, but also why.

Going back to our description of orifice tube system operation, it was illustrated that in a properly charged, properly functioning orifice tube system, the evaporator will be full of liquid refrigerant. Also, the accumulator will have about a 40% to 50% liquid level in it. As a result, the evaporator inlet and outlet temperature should be about the same. You’ll find the refrigerant is boiling (changing state) in the accumulator and there is no superheating of refrigerant taking place in the evaporator.

This contrasts with an expansion valve system where the expansion valve function prevents the evaporator from becoming fully flooded. The refrigerant boils in the evaporator and thus a certain amount of refrigerant superheating is maintained. The lower the liquid level is in an evaporator, the greater the temperature differential will be between the inlet and outlet.

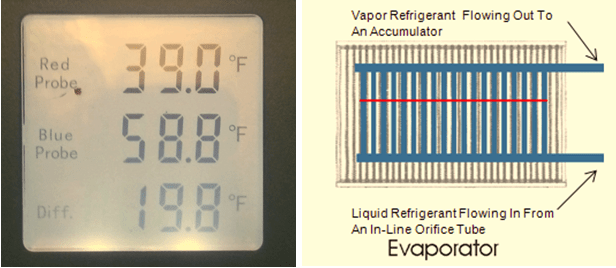

A temperature differential of about 20° indicates a low evaporator liquid level. See picture #1 below.

A temperature differential like the one pictured indicates a low liquid level in the evaporator. Instead of the evaporator being full of liquid refrigerant as it should be, the liquid level would likely be only about where the red line is drawn.

A temperature differential of 19.8° indicates a low liquid level in the evaporator. Instead of the evaporator being full of liquid refrigerant as it should be (in an orifice tube system), the liquid level would likely be only about where the red line is drawn.

There were two examples mentioned last week: 1. Where an ounce or two of refrigerant was added and there was no change in the temperature differential. 2. Where the differential was reduced to 10° with the addition of the refrigerant.

The first example is an indication of a restricted orifice tube. The reason for this is that the restricted orifice tube prevents the liquid level in the evaporator from rising. As a result, the temperature differential stays about the same.

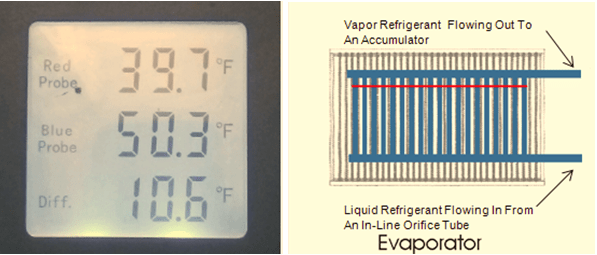

In the second example, the addition of the refrigerant brought the temperature differential down to about 10° so that indicated that the refrigerant level had risen. See picture #2 below.

With the addition of the refrigerant, the temperature differential decreased from 19.8° down to 10.6°. This indicates a rise of the refrigerant level in the evaporator and the level would likely now be about where the red line is drawn again to represent it.

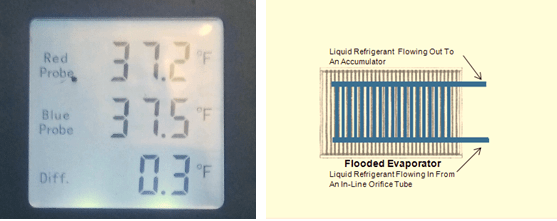

After the initial addition of refrigerant, more should be added in small increments to see if the differential can be brought down further. If the temperature differential decreases to the point where the inlet and outlet are almost the same, then that would indicate that the liquid level had risen to the point where the evaporator is now flooded.

The .3° temperature differential which is reached after the addition of more refrigerant indicates the evaporator is now full (flooded) with liquid refrigerant.

If this test was being conducted on a vehicle that just came in for service, then indications would be that a system leak was present, and the need for it to be found and fixed.

Mobile A/C diagnostics takes training and experience. Are you attending the training classes you need to provide professional service? Click here to see all the training MACS provides and click here to see the classes being offered at MACS annual Training Event and Trade Show coming up September 30-October 2, 2021 in Orlando, Florida.

Leave a Reply