Low refrigerant charge and the search for real data part 3

By Richard Hawkins, MACS contributor

The last two weeks we presented the results of part 1 and part 2 of our charge test. Now it is time to take that information and dig into it to obtain a good understanding of what it all means.

In part 1 the temperature inside the shop was 89.0°. In part 2 it was 91.5°. This test was conducted at the MACS headquarters in the month of February and the temperature outside was in the high 20s to low 30s that day.

To place as much heat load on the system as possible, we turned the heat in the shop up on high and got it as hot as possible before beginning the test. When the temperature peaked at 89°, we began the test. We tried to keep it constant, but all the heat being generated by the engine in the test vehicle caused it to inch upward by 2.5° before the second test was concluded.

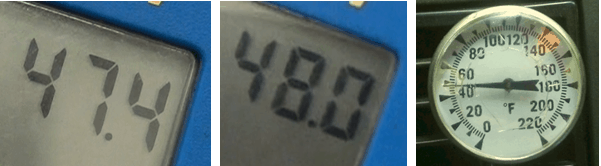

The vent temperature was 47.4° in test 1. The vent temperature was 48° in test 2. This is where things start to get very interesting, but first a reminder about something which affected these temperatures: They would have been about 5° lower for each test if we had not turned the temperature control knob up slightly to put more head load on the system to prevent system cycling.

We often associate low charges with high vent temperatures, and they certainly can have a big effect, but is it obvious that a 25% undercharge had little effect on the vent temperature here. A .6° increase in vent temperature is not a change that anyone is going to feel, and it hardly shows up on a non digital thermometer (sometimes fondly referred to as a kitchen thermometer). If fact, it is likely that the .6°increase was caused more by the 2.5° temperature increase inside the shop rather than the reduction in refrigerant charge. In any event, there was nothing in these readings which suggested any sort of issue with the refrigerant charge amount.

Picture #1: A .6° increase in vent temperature is not something that anyone is going to be able to feel and it cannot be detected on a conventional vent thermometer either.

The humidity inside the shop was 22% in test 1. The humidity inside the shop was also 22% in test 2. With it being winter, the humidity was low, and it did not change during the tests.

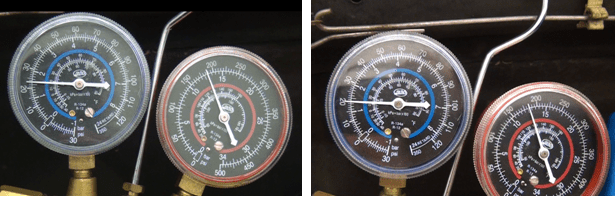

The high side pressure in test 1 was 187 PSI. The high side pressure in test 2 was 185 PSI. I have often heard the saying: I like to charge a system until the pressures look “right” and the system is blowing “nice and cool”. However, the vent temperatures and high side readings in these tests prove that charging method does not work as the pressures are what one would expect for the shop temperature and heat load and the vent temperature is cool.

NOTE: The 2.5° higher temperature inside the shop likely caused the high side pressure to be slightly higher in test 2 (maybe 2 to 3 PSI), but a 2 to 5 PSI change in high side pressure is very slight. In any event, there is nothing in these readings that would indicate any sort of issue with the refrigerant charge amount.

The low side pressure in test 1 was 23 PSI. The low side pressure in test 2 was 20 PSI. There was no cycling going on during either test due to the temperature control being turned up slightly. According to OEM information, the clutch cycling switch cycles the compressor off at approximately 20.5 PSI, so the system was operating just above that threshold in test 2.

Again, as with the vent temperature and high side pressure, there was nothing going on with this low side reading to indicate an issue with the refrigerant charge amount.

Picture #2: The pressure for test 1 are shown on the left. The pressures for test 2 are show on the right. These slight changes give no indication of any refrigerant charge related issue.

Next week we will examine the temperature readings on the various components to achieve an understanding of what they mean.

MACS members receive in-depth service and repair information to help them provide efficient repairs.

Join MACS today to tap into these great resources.

Leave a Reply