Top three tips on orifice tube behavior

By Richard Hawkins, MACS contributor

In the last four MACS blog articles we covered a lot of detailed information about orifice tube system behavior. We examined a system with a full refrigerant charge verses a 25% undercharge.

Now it is time to condense it all down into three important takeaways.

1. Pressures and vent temperatures cannot be used to determine if a system is properly charged. As indicated previously, the high side pressure dropped by 2 PSI and the low side pressure dropped by 3 PSI when the system was run with the 25% undercharge. The vent temperature only rose .6° (just over half a degree) running with the 25% undercharge, and some of that vent temperature increase could have been due to the temperature increasing by 2.5° inside the shop.

2. Large refrigerant undercharges result in increased compressor operating temperatures. With highly superheated vapor entering compressors, they are not cooled properly. In this test a 21.6% temperature increase was encountered.

3. With a large refrigerant undercharge, oil becomes trapped in the evaporator and the amount of oil in the compressor can get down to dangerously low levels. In this test, the oil amount was reduced by over 57%.

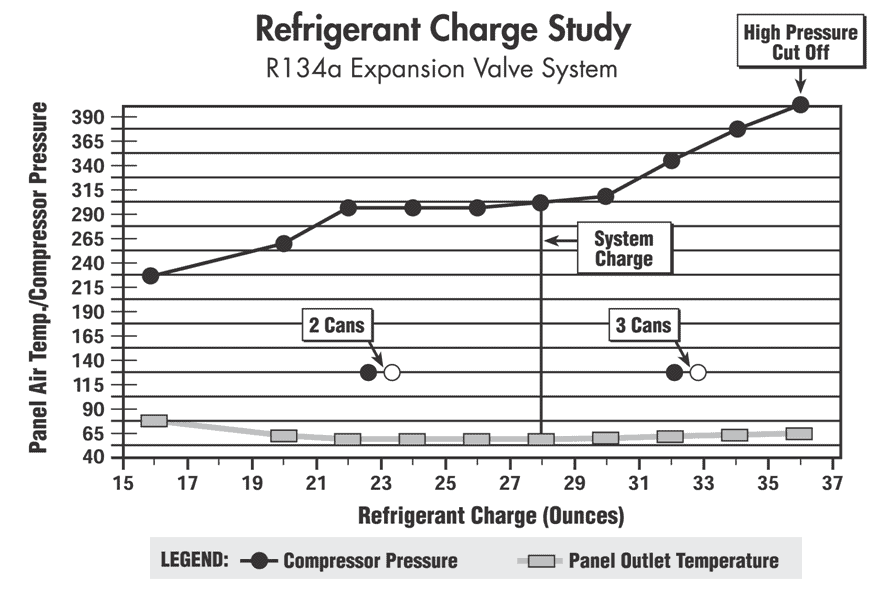

Our test was done on an orifice tube system, but a chart from a study that (MACS conducted previously) conducted on an expansion valve system shows similar results. See picture #1 below.

Picture #1: The study was conducted on a single expansion valve system that specified a charge of 28 ounces of R-134a. The ambient temperature was close to 100° which resulted in a high heat load and high side pressure which was running at about 300 PSI with the correct charge.

- Reducing the charge from 28 ounces down to 26 ounces resulted in a 5 PSI pressure reduction (from about 300 PSI to about 295 PSI).

- The pressure stayed constant at about 295 PSI with a 26-ounce charge all the way down to a 22 ounce charge.

- A sharp drop in pressure of 20 PSI occurred when the charge was reduced an additional ounce (from 22 ounces down to 21 ounces).

The reduction down to 21 ounces resulted in an overall 25% undercharge. If we do a direct comparison to the orifice tube test, we can see that the expansion valve system was more sensitive to the reduction in refrigerant charge. However, until the charge was reduced below 22 ounces (which was a 21.4% reduction) there was very little change in high side pressure.

The chart does not show the low side pressure, but it does show the vent temperature (referred to as panel temperature). It stayed very consistent at about 55° all the way from a 22-ounce charges up to 30 ounces.

Something else which this study illustrates is how someone might easily undercharge this system if they were charging with 12-ounce cans and trying to guess at getting 28 ounces into the system.

There are two white dots (one titled “2 cans” and the other titled “3 cans”) which indicate the pressure range experienced with 2 to 3 cans in the system. After charging two cans into the system, a third can would be connected and then guesswork would be employed to try to get the charge to 28 ounces. With the high side pressure, the same from the 2 can mark up to 26 ounces and the vent temperature staying the same, there is a high probability that an undercharge would result using cans.

The bottom line is that accurate charging equipment must be used to insure accurate refrigerant charges.

If you like our blog content, MACS Membership will provide you with more in-depth training information to make intelligent and efficient repairs. Join MACS as a member today.

Leave a Reply