What type of condenser is in that vehicle?

By Richard Hawkins, MACS contributor

What type of condenser is in that vehicle?

It is a frequent question in the mobile A/C industry. It can occur when ordering condensers and in tech calls, too. We mentioned three types of condensers that could currently be supplied for the older (94-02) GM trucks in last week’s article.

I have asked that same question hundreds of times during tech calls. Often, it was necessary to explain how to tell the difference to get an answer. In this and next week’s article, we will do just that.

Four types of condensers

Before getting into the details, it is helpful to have some history on the evolution of condensers in mobile A/C. There have been four types used:

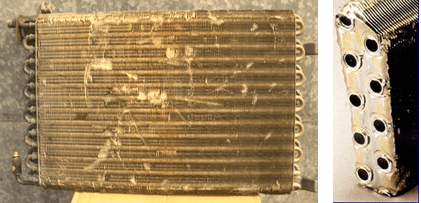

- 3/8″ tube & fin condensers: Used by the OEMs from the early days of mobile A/C into the 1990’s on cars and light trucks. See picture #1 below.

Picture #1: A 3/8″ tube & fin condenser is shown on the left. On the right is a cut-away of what it looks like on the inside.

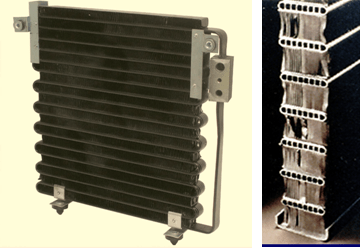

- Serpentine condensers: Were the first style used by the OEMs in place of 3/8″ tube and fin units. First appeared in the early to mid-1970’s in some Japanese cars. Came into common use in the mid 1980’s on cars and light trucks and were used by the OEMs on in to the early 2000’s.

Picture #2: A serpentine condenser is show on the left. On the right is a cut-away of what it looks like on the inside.

- 6mm condensers: Sometimes referred to as 6mm piccolo condensers. Were introduced by the OEMs in the mid 80s on cars and light trucks and they used them up through the late 2000’s.

Picture #3: A 6mm condenser is shown on the left. On the right is a cut-away of what it looks like on the inside.

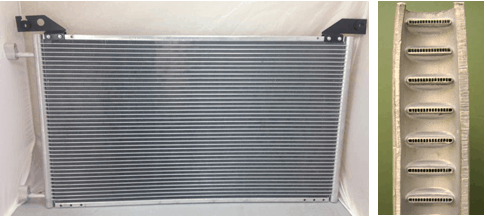

- Parallel flow condensers: Introduced by the OEMs in the early 1990’s. Regarded as the most efficient condenser design. Gained widespread use during the transition from R-12 to R-134a. Currently being used by all the OEMs in new cars and light trucks in the U.S market.

Picture #4: A Parallel flow condenser is shown on the left. On the right is a cut-away of what it looks like on the inside. Photo Courtesy of MACS member Ranshu Inc.

The evolution in condensers has been driven by the need for smaller, lighter weight, more efficient units. As a result, copper which was used to construct the tubes of 3/8″ tube & fin condensers, was replaced by aluminum in the serpentine, 6mm and parallel flow designs.

Also, the characteristics of R-134a required condensers which were more efficient. The inside diameter of a 3/8″ tube and fin condenser is about the same size as a #2 pencil like we used back in elementary school. This results in a lot of refrigerant inside the tube that is not in direct contact with any metal.

One of the keys to making condensers more efficient is to make the internal passages smaller. This gets more refrigerant directly in contact with the metal surfaces improving heat transfer. As condensers have evolved, the inside passages have increasingly gotten smaller. Notice the cut-away pictures of each unit above.

Check back in next week and we will provide some detailed information to help easily determine the answer to: What type of condenser is in that vehicle?

Join MACS as a member to access more valuable technical mobile A/C information.

Leave a Reply