Two clues to a condenser’s identity

By Richard Hawkins, MACS contributor

There are two clues or steps to determining what type of condenser is in a vehicle.

The first step is to determine the shape of the horizontal tubes which the refrigerant flows through. Are they round or are they flat? If they are round, then the unit will be either a 3/8″ tube and fin or a 6 mm. If they are flat, then the unit will either be a serpentine or parallel flow.

Once the shape of the tubes is determined, the second step is to determine how the unit is constructed on each end.

Detailed information on that is included below.

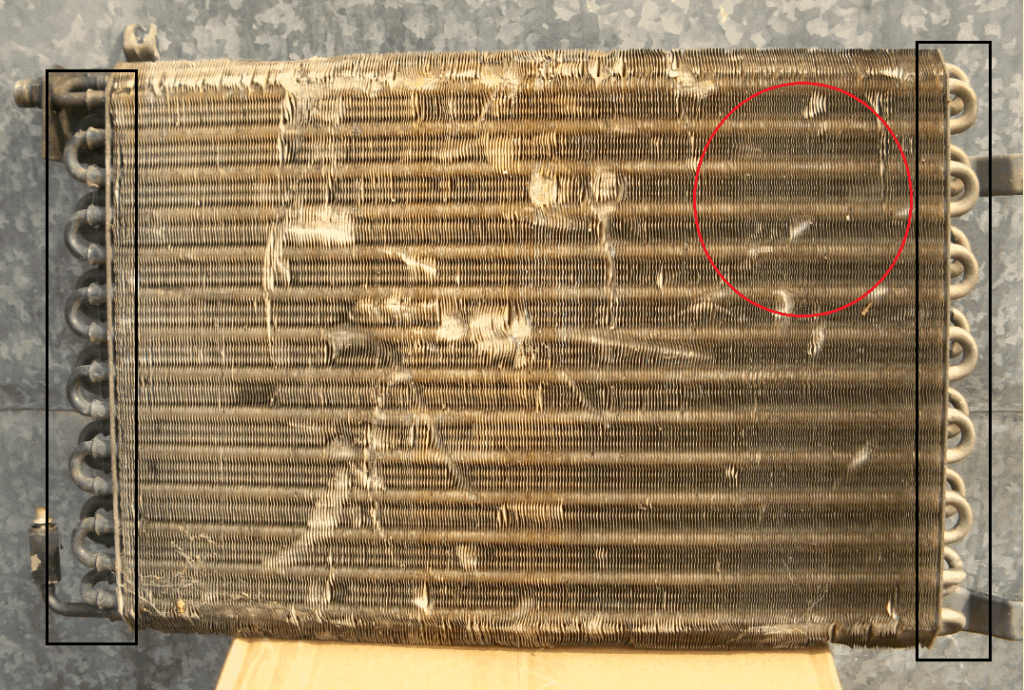

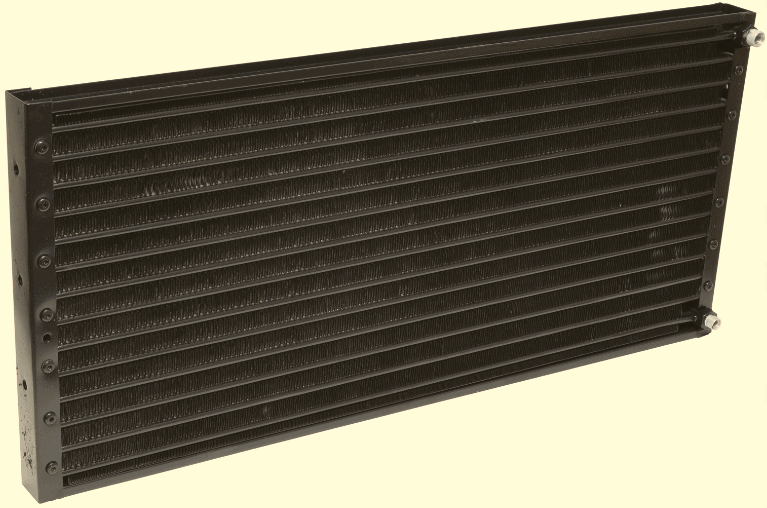

First, we will look at the 3/8″ tube and fin condenser. The inlet on 3/8″ tube and fin condensers connects to a fitting that is shaped like a U. This fitting is connected to two 3/8″ tubes. These tubes run horizontally back and forth through the condenser core. At each end are more U-shaped fittings which create 180° bends and route the refrigerant back across the core. See picture #1.

Picture #1: Notice the round tubes inside the core (circled in red) and the 180° bends on each end (in the black boxes). Those characteristics are the key in determining this is a 3/8″ tube and fin condenser.

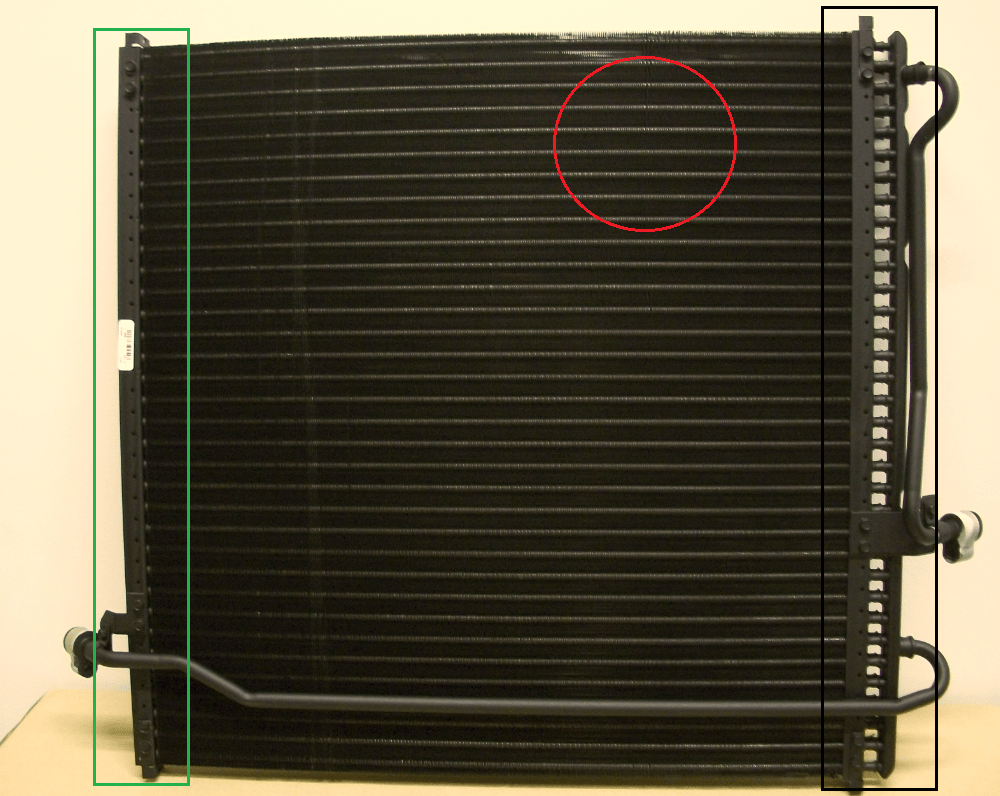

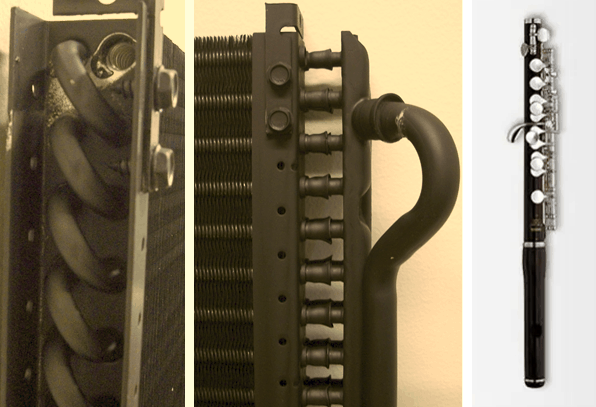

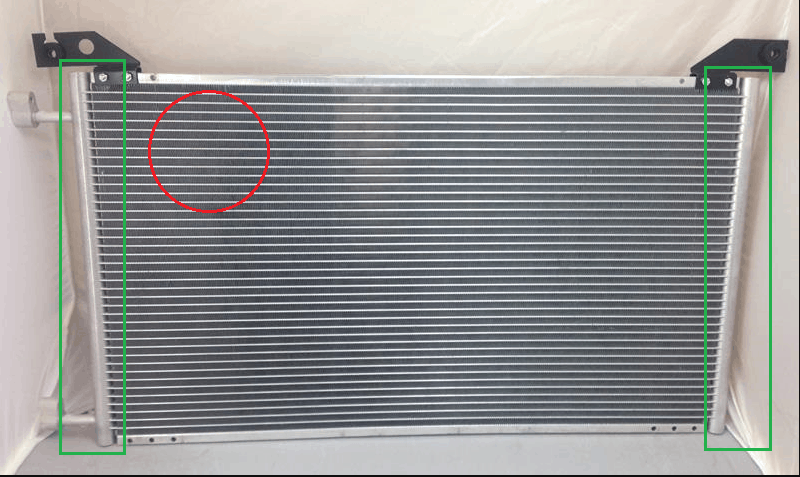

Next, we will look at the 6 mm condenser. As indicated, it too has round tunes. At 6 mm in diameter, they are noticeably smaller than 3/8″ tubes (3/8″ converts to 9.53 mm). These tubes run horizontally back and forth through the condenser core. On one side are U-shaped fittings which create 180° bends which route the refrigerant back across the core. On the other side are two manifolds which the tubes connect to. These manifolds resemble the musical instrument piccolo. A piccolo looks like a small flute and that is where the name 6 mm piccolo condenser comes from. See picture #2 & #3.

Picture #2: Notice the round tubes inside the core (circled in red). The 180° bends are behind the framework on the left (in the green box). The manifolds which resemble a piccolo are on the right (in the black box).

Picture #3: On the left is a close-up shot of the 180° bends. In the center is a close-up of the piccolo manifold. On the right is an actual piccolo.

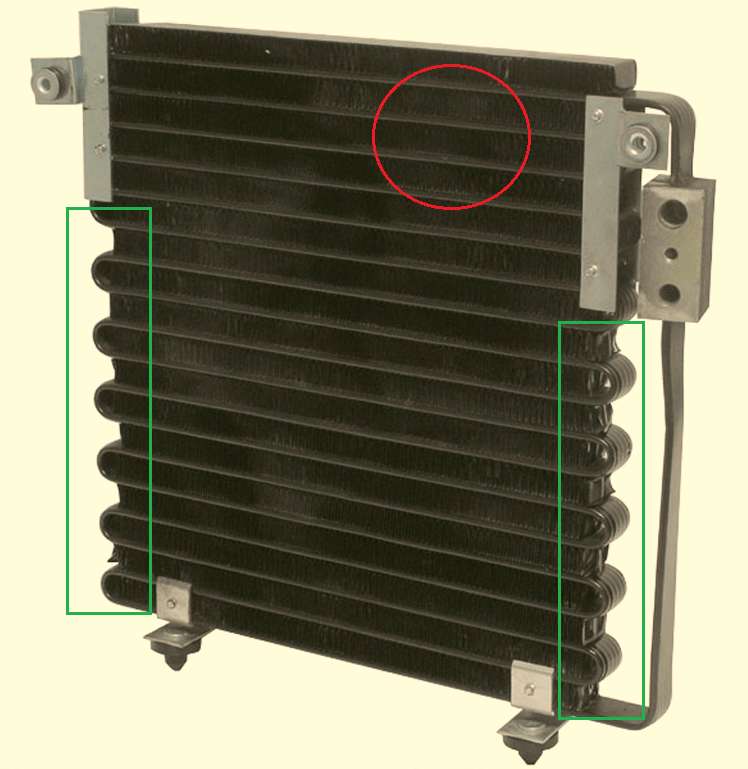

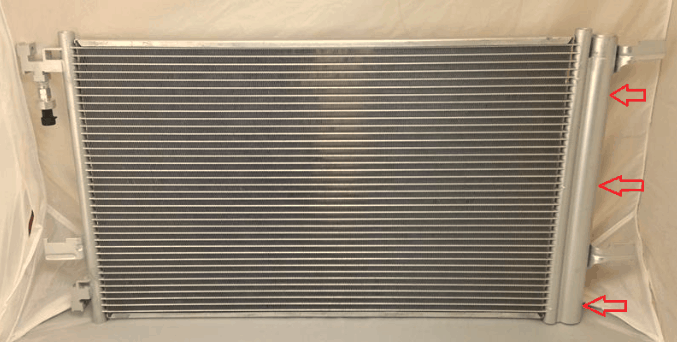

Now, it is time to examine the units with flat tubes, with the serpentine being first. An internet search of the word serpentine reveals there are several definitions which come up. One of those is “winding or twisting like a snake”. That seems to be a very appropriate name for this type of condenser. That is because they are constructed from a flat piece of tubing which winds back and forth. The tubing is bent 180° on each end. Sometimes it can be difficult to see the bends because they are covered by part of the condenser frame. As a result, it can sometimes be easy to mistake a serpentine condenser for a parallel flow. See pictures #4 & #5.

Picture #4: Notice the flat tubes (circled in red). Notice the 180° bends (in the green boxes).

Picture #5: The 180° bends are not visible because of the frame rails on each side. As a result, this serpentine condenser could be mistaken for a parallel flow unit easily if not examined carefully. Photo courtesy of MACS member UAC parts.

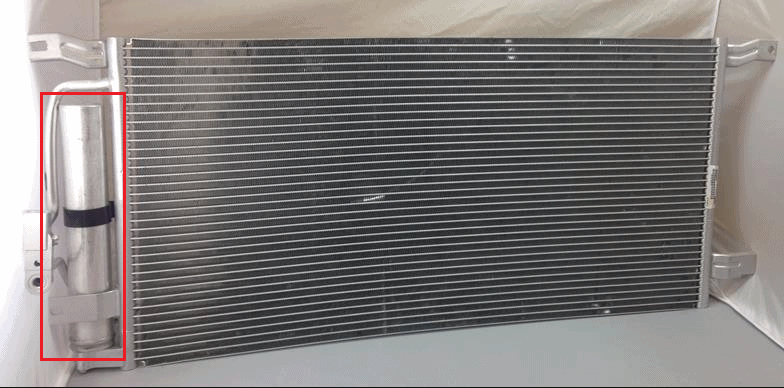

Finally, we will look at the parallel flow condenser. As mentioned above, it has flat tubes. Unlike the serpentine, it has manifolds on each end. Sometimes the manifolds will be round. Sometimes they will have a square or somewhat rectangular shape. Parallel flow condensers often have a hollow canister attached to them which houses a replaceable drier. Some use driers which are detachable. See pictures #6, #7 & #8.

Picture #6: Notice the flat tubes (circled in red). The manifolds are on each end (in the green boxes). Photo courtesy of MACS member Ranshu Inc.

Picture #7: This unit has a hollow canister (indicated by the red arrows) which houses a replaceable drier. Photo courtesy of MACS member Ranshu Inc.

Picture #8. This unit has a detachable drier (in the red box). Photo courtesy of MACS member Ranshu Inc.

Hopefully this will help streamline the process of determining “what type of condenser is in that vehicle” when the question comes up.

A special Thank You goes out to MACS member Auto Parts Components for providing information used in this and last week’s articles.

Real-world, unbiased technical information is available when you become a member of MACS.

Join here!

Leave a Reply