Mind the compressor clutch gap

By Richard Hawkins, MACS contributor

Tech calls involving compressor clutch issues are common. They often involve problems that occur after a compressor has been in operation for a short period of time. However, sometimes problems can occur right at initial system start-up when the system is performance tested.

One of the first things I was taught in my A/C training was to always check the clutch air gap prior to installing a compressor. I have heard this echoed over and over since that time in other training classes and it is something that MACS recommends. However, most technicians don’t seem to be doing it.

A commonly asked question on tech calls involving clutch issues is: Have you checked the clutch air gap? Unfortunately, all too often the answer is no.

Then that is often followed up with something like: “The clutch is supposed to be gapped correctly at the factory; I should not have to check it.” I would agree with the first part of that statement. However, there are many reasons why someone should check the clutch air gap. So, we shall examine them.

A compressor is handled many times before it reaches a shop. It is taken off the assembly line and put in the box. It then might be placed on a shelf for temporary storage or put in a crate for immediate shipment. After shipment, it will be removed from the shipping crate and put on a warehouse shelf.

Then it will be removed from the warehouse shelf and shipped to a store. It will be put on a shelf there and later removed again and put on a delivery truck. Then it is taken to a shop where it will be handled a couple of times again. If the steps that are involved are counted, a compressor can easily be handled a dozen times or more from the time it is removed from the assembly line until it arrives at a shop.

Most manufacturers use packaging which protects clutches, but rough handling can alter a clutch air gap or even damage a clutch where the clutch hub gets bent. That by itself is reason enough to check a clutch air gap, but there are more.

Gap gaffs

Despite quality control measures manufacturers employ, sometimes a clutch just ends up with an incorrect air gap.

- The air gap can be too wide, which can result in clutch slippage or the clutch not engaging at all.

- The air gap can be too small, which can cause the clutch to drag when it is disengaged.

- There may be no air gap at all, where the clutch hub is tightly pushed up against the friction plate on the pulley. Depending on how tight it is, the clutch might either drag or stay engaged all the time.

Checking a clutch air gap does take a bit of extra time, but that is time which is well invested. Many times, I’ve spoken with someone who had a clutch issue that was discovered at initial start-up. Unfortunately, it wasn’t diagnosed until I asked them to check the clutch air gap. If the air gap had been checked prior to installation, the issue could have been resolved before installing the compressor. If a compressor is easily accessible, adjusting a clutch air gap might not be too time consuming. But with the way modern vehicles are constructed with everything under the hood so tight, often a compressor will have to be removed.

Picture #1: This is a slide from a MACS A/C Clinic. It is some excellent advice.

This is not to imply that clutch air gap issues are an everyday thing. However, if you do enough A/C work, it is highly likely you will encounter a clutch air gap problem somewhere along the line. As fate might have it, it will probably be on a vehicle where the compressor is buried. As a result, removing and re-installing it might be necessary to adjust the air gap and it might take hours.

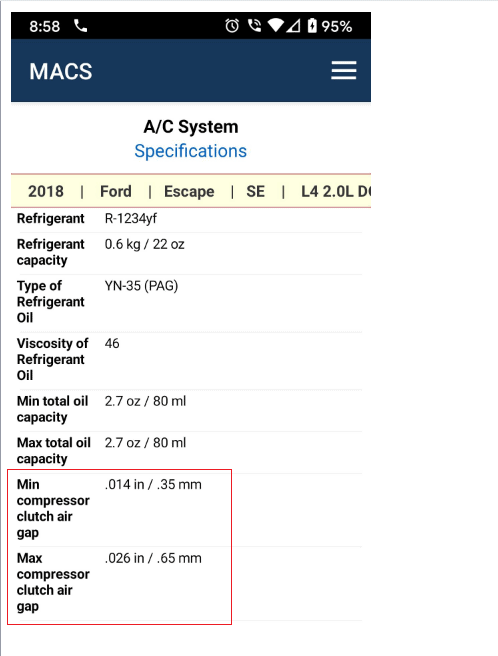

An excellent source of information for clutch air gaps is the MACS mobile diagnostics APP available only to dues paying members.

Picture #2. Here is a screenshot from the MACS APP which provides clutch air gap information as well as other valuable A/C system information from the Motor A/C and engine specifications guide for automobiles and light duty trucks.

If adjusting a clutch air gap, it is advisable to aim toward the low end of the air gap range. This will allow the air gap to remain within specifications longer as the gap will widen over time due to wear.

If you want to use MACS app you must purchase a membership. MACS mobile diagnostics APP is one of MACS top member benefits and it puts A/C specs in the palm of your hand. Click here to become a MACS member!

Leave a Reply