Electronically controlled variable displacement compressors

By Richard Hawkins, MACS contributor

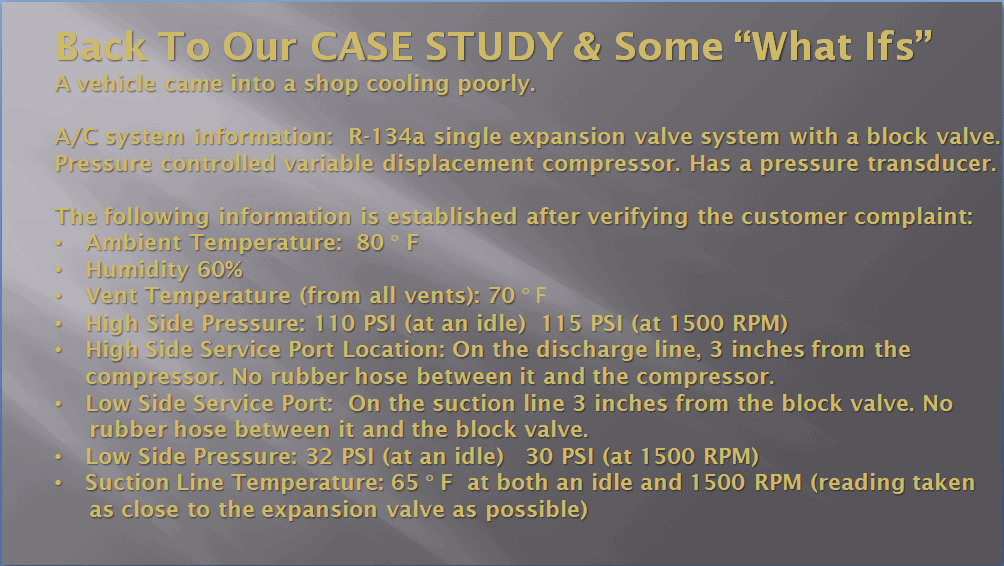

Continuing our series of “What Ifs” from last week’s article: We will go back to our case study which began this series of articles. This of course used a pressure controlled variable displacement compressor and an expansion valve system and there was a problem with a restricted expansion valve.

Picture #1: The original case study.

Picture #2: The case study questions.

Picture #3: The correct answer.

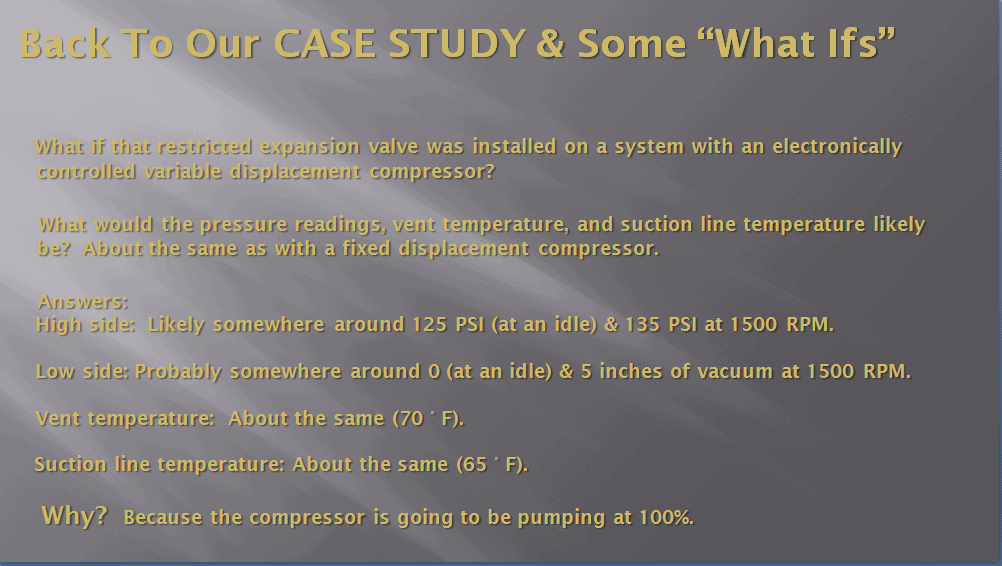

So “what if” this system used an electronically controlled variable displacement compressor instead of the pressure controlled variable displacement compressor? What would the results be?

Picture #4. The “”what if” change and results.

As the picture indicates, the results would be very similar to the results with the fixed displacement compressor. Why? Because the output of the electronically controlled variable displacement compressor is determined in large part by the temperature of the evaporator.

There are many different inputs the computer utilizes to determine the amount of compressor displacement needed. However, the input that has the biggest impact on compressor displacement is the evaporator temperature. This input is provided by either an evaporator temperature sensor which is placed in contact with the upper portion of the evaporator or a discharge air sensor which is placed in the air stream exiting the evaporator. Please see picture #5.

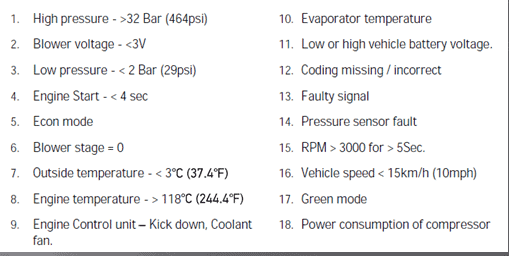

Picture #5: Here is an example of 18 different inputs that a Volkswagen uses to determine compressor displacement.

As indicated, the evaporator temperature has the most influence. With just a small amount of refrigerant flowing through the evaporator due to the restricted expansion valve, there will be a very low liquid level in the evaporator. This will cause a lot of refrigerant superheating and the area of the evaporator where the evaporator temperature is placed in contact with will be about 65° F. If the system uses a discharge air temperature sensor, the air temperature will be about 70° F.

The computer is programmed to provide enough compressor displacement to keep the evaporator temperature low enough to provide sufficient cooling. When the evaporator temperature is high, the computer is going to command the compressor to operate at full displacement. With the unit at full displacement, it will be behaving like a fixed displacement compressor.

Technical content is at the heart of MACS mission to the mobile air climate industry.

Use this QR code to join MACS as a member for access to more quality technical information.

Leave a Reply