Air contamination in an A/C system can ruin your day

By Richard Hawkins, MACS Contributor

In my two previous blog articles, I covered some tests which were conducted to illustrate the effects of air contamination on a mobile A/C system.

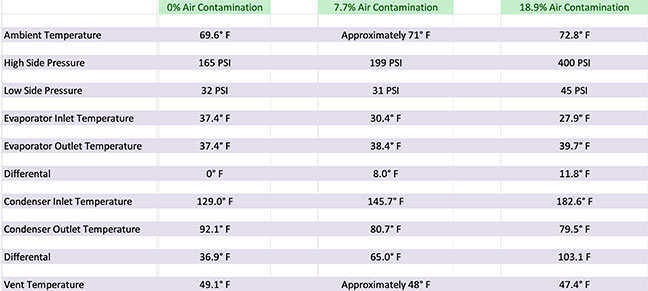

First there was a base line test with 0% air contamination. That was then followed by tests with 7.7% and 18.9% air contamination. Below is a chart which provides that information for easy comparison. Please see figure #1.

Refrigerant recovery and recycling, retrofitting (from R-12 to R-134a) and refrigerant identification are three things that were introduced to the mobile A/C industry in the 1990s. The days of retrofitting are long past us. However, refrigerant recovery and recycling and refrigerant identification still hold a very prominent place in the word of mobile A/C service and will continue to do so.

I had a memorable encounter with air contamination in the mid 1990s. I was conducting a lot of retrofit clinics at the time and had recently acquired a demo refrigerant identifier which I took to those clinics. At one clinic, there was a technician who was extremely interested in the refrigerant identifier.

He was a young technician (probably only a couple of years out of high school). There was a lot of interest in the refrigerant identifier at clinics because they were relatively new to the industry. As a result, technicians often asked a lot of questions about them, but his interest level was off the charts.

After the clinic was over, he came up front and asked more questions about the refrigerant identifier.

Finally, he asked: How long are you going to be in town tomorrow? Then the conversation went something like this:

Me: I’ll be around until about 11:00AM. Then I’m headed to Baltimore to do a clinic there tomorrow night.

Technician: Will you be driving up I-95?

Me: Yes, for sure. That’s the fastest way to Baltimore.

Technician: Our shop is located less than an 1/8 of a mile off I-95 and you will be going right by there. Is there any possibility you might be able to stop by and hook that refrigerant identifier up to a car I’m working on and, also to the “freon” tank I’m charging from? I’ve got a car that is “kicking my butt” and after hearing about that refrigerant identifier, I think there is a good chance the “freon ” is contaminated.

Me: Sure, would it work to stop by around 11:30?

Technician: Whatever time will work for you will work for me.

The next day I arrived at the designated time. I do not recall the model or year of the car, but it had an R-12 system, and he was charging it with recycled R-12. The shop had a relatively new all manual R-12 recovery/recycling machine. The conversation went something like this:

Technician: Thanks for stopping by. I haven’t done a lot of A/C work before and the shop doesn’t do a lot of A/C work, but we are looking to do more since the owner bought the recovery/recycling machine. I’ve been working on this car for almost a week and have replaced the fan clutch, condenser and some hoses and charged it up more times than I can count. The problem with it is the high side pressure is way too high. It’s getting over 400 and the high-pressure cut-out is turning the compressor off and on.

Me: Well, that could be caused by refrigerant contamination. Let’s hook the refrigerant identifier up to the car and see if the refrigerant is contaminated.

I proceeded to connect the refrigerant identifier to the car and test the refrigerant and in a very short amount of time, what I had suspected was confirmed. The refrigerant was indeed contaminated. There was no cross contamination with other refrigerants, but the percentage of air was about 20%.

Continuing the conversation:

Me: Look’s like we’ve found your problem. The refrigerant is contaminated with air. The percentage is about 20%.

Technician: Man, I sure am glad to find out what the problem is.

Me: Let’s check the tank you’re charging from and see how that checks out.

We proceeded to check that tank and it had about the same percentage of air. This was a tank that had been on the recovery/ recycling machine they had been recovering refrigerant in to. Continuing the conversation:

Me: Your charging tank has about the same amount of air contamination. How often do you guys check your recycled refrigerant for non-condensable gases?

Technician: What do you mean?

Me: When you got your refrigerant handling (Section 609) certification, there was a procedure covered in it for checking for the presence of non-condensable gases (that’s the term they use for air). How often do you conduct that test?

Technician: I don’t have a certification, so I don’t know what you’re talking about.

I proceeded to explain to him the need for the Section 609 certification and how to get it. I also explained to him how to do the non-condensable gas check and how to purge the air from the refrigerant.

He called me the next day to fill me in on how things were going. He said he recovered the contaminated refrigerant, purged the air from it, charged the car back up and the system worked perfectly.

If you’re not yet Section 609 certified, you can obtain your certification here on the MACS website.

You can learn even more about mobile A/C service and repair when you join MACS as a member.

Leave a Reply