Vacuum pump maintenance

By Richard Hawkins, MACS contributor

As mentioned in last week’s blog post, vacuum pumps require regular maintenance and frequent oil changes. We wanted to provide information on the intervals, so we polled several vacuum pump suppliers.

The most frequently encountered interval was: After every use.

Another was: Every 10 hours of use.

Another was: Every 25 hours.

Another was: Every week during heavy usage.

One manufacturer who recommended changing after every use also stated the following: “If the pump has been sitting for more than one month, the oil is considered contaminated and should be changed”.

Though the intervals varied, it is safe to say that all recommended frequent changes.

NOTE: Check your owner’s manual or with the manufacturer of your vacuum pump to get specific oil change interval information for your unit.

When you think about cars and light trucks having engine oil change intervals of 3,000 to over 7,000 miles, and A/C compressors not having oil change intervals at all, that brings up the question: Why do vacuum pumps have such short oil change intervals? The answer is because the oil that is used in vacuum pumps is very hygroscopic (absorbs moisture easily and retains it.)

The oil in vacuum pumps is subjected directly to the air that is removed from an A/C system when pulling a vacuum and air contains moisture. The amount of moisture varies based on geographical location and humidity, but all air contains some moisture.

Vacuum pumps use a rotary vane design and moisture affects the oil’s ability to seal between the vanes and the walls of the chamber the vanes are rotating inside of. This of course reduces a vacuum pump’s efficiency. Contamination can cause oil to become discolored Please see picture #1.

Picture #1: The oil in the picture of the vacuum pump sight glass on the left was discolored, which indicates contamination. This is the same sight glass in the picture on the right after the oil in this vacuum pump was changed. There is some slight discoloration in the lower part of the sight glass in the picture on the right. This was due to a small amount of the contaminated oil remaining in the sight glass.

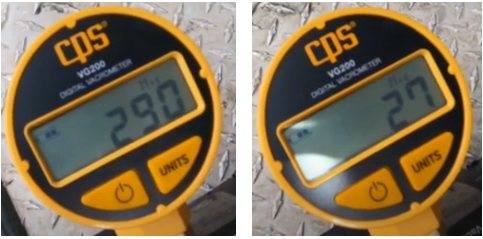

The only way to determine if a vacuum pump is functioning properly is to use a micron gauge. A regular gauge on a manifold gauge set just does not have the necessary accuracy. It is common for the vacuum level to improve by 200 to 300 microns when changing oil during regular change intervals. If the oil is badly contaminated, there will be a greater improvement. Please see pictures #2 and three.

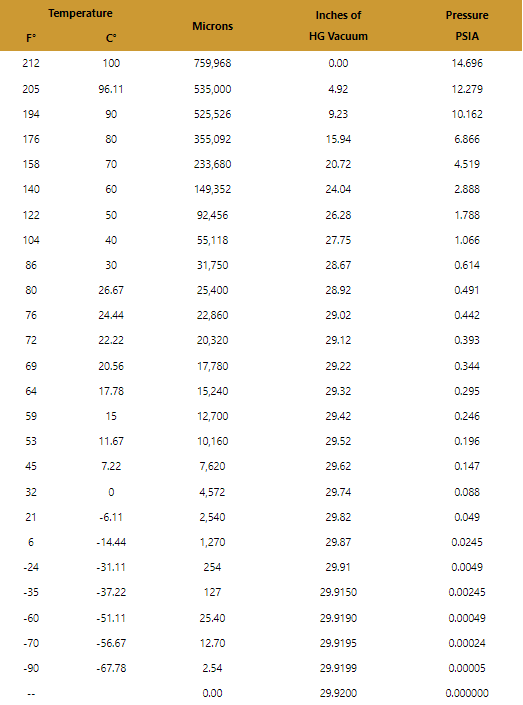

Picture #2: This chart illustrates the relationship of microns to inches of Hg. It is common for the gauge on a manifold gauge set to easily be off by one inch of Hg or more. One inch of Hg = 25,400 microns. That is why only a micron gauge can be used to determine vacuum pump efficiency.

Picture #3: The picture on the left shows a reading of 290 microns on a micron gauge. The picture on the right shows a reading of twenty-seven microns on the same micron gauge. The picture of the left was taken when a vacuum pump achieved its lowest micron level prior to the oil being changed. The picture on the right was taken immediately after the oil was changed and the vacuum pump again achieved its lowest micron level.

Badly contaminated oil with a high moisture content can corrode the rotor, vanes, and chamber inside of a vacuum pump and ruin it, so that is another compelling reason for changing vacuum pump oil often.

A couple of tips on changing vacuum pump oil:

- If there is doubt about when the oil was changed or if it is contaminated, then it should be changed.

- Make sure the pump is warmed up before you drain the old oil out. This helps insure that contaminates which might be present inside the oil chamber will mix with the oil and be removed in the draining process.

MACS members are constantly updated with relevant technical information, Join MACS today as a member.

Leave a Reply