The importance of A/C system oil balancing

By Richard Hawkins, MACS

Editor’s note: My past three MACS blog articles have focused on A/C system oil capacity information and how it can sometimes be misleading and result in the incorrect amount of oil put in a system. (Links for referral to Blog 1, 2 ,3)

This is such an important part of doing A/C service work properly, it deserves summarizing before moving on to a different topic.

In Summary:

1. Sometimes we encounter information where directions instruct us to drain the compressor being removed from a system and measure the amount of oil that drains out. Then the next step is to subtract this number from the number of ounces that are supposed to be in the shipped replacement compressor.

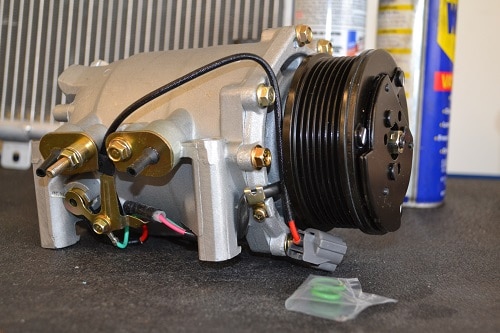

Then the next step is to drain that amount of oil from the replacement compressor. This is supposed to result in the same amount of oil being in the replacement compressor as there was in the compressor removed from the system. This is known as oil balancing. Please see figure #1.

Figure #1: The procedure referenced directly above as described by an information provider. This is OEM information.

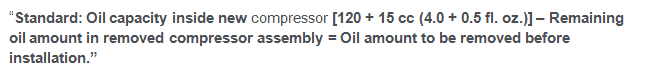

2. We might also be instructed to drain the oil from the compressor being removed from the vehicle and measure it. Then drain the oil shipped in the replacement compressor and install the same amount that was drained from the compressor that was removed from the vehicle into the replacement compressor. This is also known as oil balancing and this method is less complex. Please see figure #2.

Figure #2: The procedure referenced directly above as described by an information provider. This is OEM information.

Simply put, oil balancing means that the same amount of oil that is being removed from a system is being reinstalled. If oil balancing a compressor is being done, then example #2 would be the preferred way to achieve this. This is because example #1 “assumes” that the replacement compressor contains a certain amount of oil. Example #2 removes that assumption and also saves some time as the math exercise is eliminated.

Some OEM information would lead you to believe that oil balancing of a compressor always needs to be done when a compressor is being replaced. But this is simply not the case. Oil balancing applies when there is some oil in the system.

An example would be where just a compressor is being replaced because of a seal leak (no other components replaced and no flushing). If a compressor is being replaced on a dry system (where there has been component replacement and flushing and no oil remains), then oil balancing is not necessary and is a waste of time if done. (This is not to suggest that oil from the original compressor should not be drained and examined to get an idea of how dirty the oil in a system might be.)

When a compressor is installed at the vehicle assembly plant, there is no oil balancing that takes place there and installing a compressor on a dry system is no different than the installation of a compressor at the vehicle assembly plant. A full system charge of oil needs to be installed in the compressor and it should be rotated about a dozen times by hand before the system is turned on for performance testing. As A/C systems have evolved, lubrication information has gotten more complex. Some excellent additional information on this topic is from an article that appeared in the January/February 2018 addition of MACS ACtion Magazine titled Our Struggle With Oil.

MACS membership is all about the importance of proper A/C service and repair. Join MACS as an association member!

Leave a Reply