An RRR Machine Test

By Richard Hawkins, MACS contributor

At the end of last week’s article, I referenced an R/R/R machine test.

The purpose of the R/R/R machine test was to compare the recovery capability of two different R-134a R/R/R machines. One was an older machine which met the old SAE standard J2210. The other was a newer machine which met the SAE standard J2788 which was adopted in 2007and is still the latest standard for R-134a machines. If you have not already read last week’s article, click here.

Here is information on the equipment used in the test and test conditions.

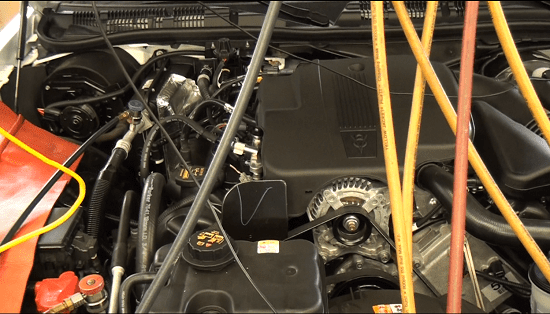

Test vehicle: 2011 Ford Crown Victoria with a 27-ounce refrigerant capacity. Please see picture #1.

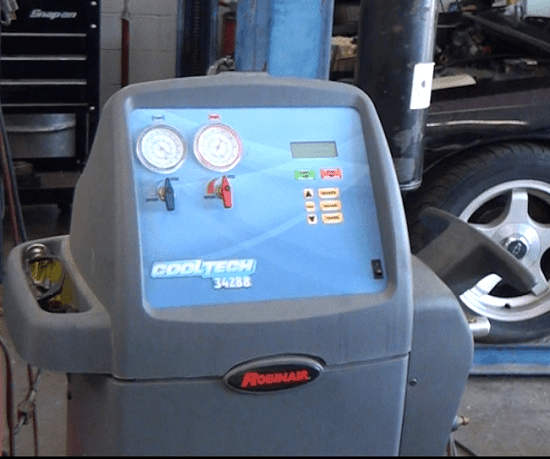

R/R/R machine #1: A J2210 R/R/R machine. Please see picture #2.

R/R/R machine #2: A J2788 machine. Please see picture #3.

Ambient temperature: 66° to 67° F.

The first step was to recover the refrigerant from the vehicle with the J2788 machine. The J2788 standard requires a machine to recover 95% of the refrigerant from a system within 30 minutes or less with no heat added to the system. It must also weigh it with an accuracy of plus or minus one-half ounce.

After completing the recovery, the J2788 machine was used to charge the car with twenty-seven ounces of refrigerant. The J2788 standard requires a charge accuracy of plus or minus one-half ounce. The A/C system was then run for a short period of time to ensure that the refrigerant was distributed properly throughout the system.

The next step was to recover the refrigerant with the J2210 machine. The machine’s operators’ manual states the following regarding recovery: “The unit will remove refrigerant from the vehicle system until it reaches six inches of mercury–that is a six-inch vacuum. When this vacuum is reached the compressor will automatically turn itself off and go into a two-minute hold period to make sure that the system stays in a vacuum. If at any time during the two-minute hold period the vehicle system pressure rises to a positive 2 PSI, the recovery process will automatically restart and once again pull the vehicle’s system down to a six-inch vacuum.”

During the recovery process, the pressure did rise several times and the machine turned back on. To insure that as much refrigerant was recovered as possible, the recovery process was started over after the machine had shut off for good indicating the recovery was complete. The total amount of time that elapsed during recoveries was 30 minutes. This machine was not equipped with a display which indicated how much refrigerant had been recovered.

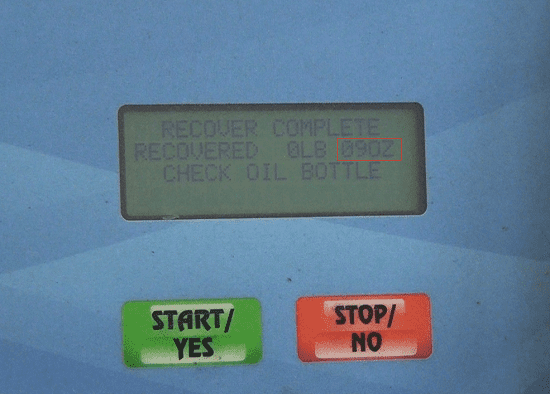

After the recovery was “complete” according to the older machine, we connected the J2788 machine up to the car and started recovering refrigerant. Please refer to picture #4 for the amount recovered.

As indicated in the picture, the older machine left 9 ounces in that system. That is 33% (1/3 of a 27 ounce) refrigerant charge.

I had expected it to be significant, but not that much. Based on information that I had read and a conversation I’d had with someone who conducted a similar test, the amount was expected to be about 20% to 25% (about 5 1/2 to 6 3/4 ounces).

So why do the older J2210 machines leave so much refrigerant in a system?

It has to do with the vacuum level the machines turn off at. As indicated above, the operator’s manual for the J2210 machine used in this test states the following: “The unit will remove refrigerant from the vehicle system until it reaches six inches of mercury–that is a six-inch vacuum. “The operators manual for a J2210 machine from a different manufacturer stated the following: “The compressor shuts off automatically when recovery is complete (at approximately 17 in. HG).” In this test, the machine we used would turn off at about 12 to 15 inches HG.

The operator’s manual for the J2788 machine used in this test states the following: “When the system has recovered to 0 PSI, the vacuum pump starts and runs until recovery is complete.” A properly functioning vacuum pump is going to pull a vacuum much greater than the 6, or 12 to 15, or 17 inches HG that the J2210 machines pull, so that is why the refrigerant recovery is so much greater with the J2788 machines.

Check back in next week and we will explore issues related to large amounts of refrigerant being left in a system after recovery.

Join MACS as a member to stay aware of All the information you need for mobile A/C service and repair.

Have you visited MACS Facebook page at facebook.com/MACSMobileAir

Leave a Reply