A Sure Sign Of A Restriction

By Richard Hawkins

In the January 4th blog article, we covered a tech call that involved a customer who was experiencing an issue with the low side of an A/C system going into a vacuum. Unfortunately, he thought that indicated a bad compressor and as a result the call ended up taking some memorable twists and turns. If you have not already read that article, it can be referenced here: https://macsmobileairclimate.org/2023/01/04/a-memorable-tech-call/

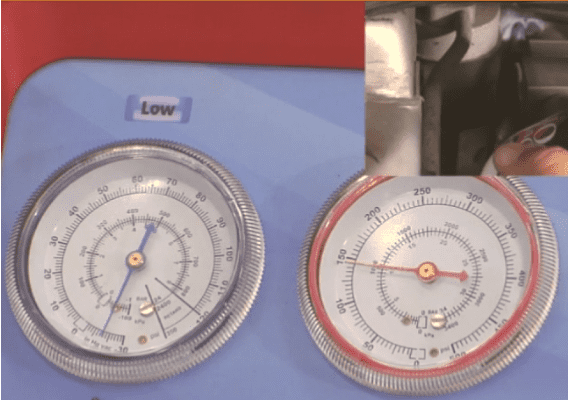

The technician was working on a single expansion valve system with a fixed displacement compressor. The high side was running about 120PSI and the low side was at a vacuum level of about 20 inches (similar to what is seen in picture #1 below). This is a condition that is encountered frequently on an A/C tech line and is a sure sign of a restriction in the system. What is occurring is that the restriction will not allow enough refrigerant flow for the high side to achieve a normal pressure level and the low side is pulled down into a vacuum. Based on conversations from over the years, there is usually about an 80% chance the restriction is expansion valve related, 15% chance it is drier related and 5% chance it is somewhere else. In this case the expansion valve was plugged up with some debris and when it was cleaned and the system was reassembled and charged back up, it worked fine.

As mentioned earlier, this system used a fixed displacement compressor, but a very large percentage of vehicles are now using variable displacement and variable output compressors. As a result, it is important to understand how a restriction like this might affect a system with a variable displacement compressor or variable output compressor.

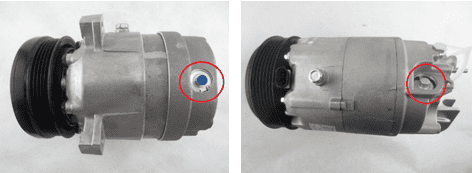

First it is necessary to understand that there are different types of variable displacement compressors and variable output compressors. The first type of variable units that were used in mobile A/C were equipped with a mechanical control valve (there are also sometimes referred to as pressure control valves). These control valves are directly exposed to the pressure in the low side of the compressor, and they control the low side pressure by varying the compressor displacement. Examples of these compressors are the GM V5 which was introduced way back in the mid-80s and the GM CVC. Please see picture #2.

Some rotary vane and scroll compressors were also introduced that use mechanical control valves. They control the low side pressure by use of internal by-passes which control compressor output rather than varying the displacement.

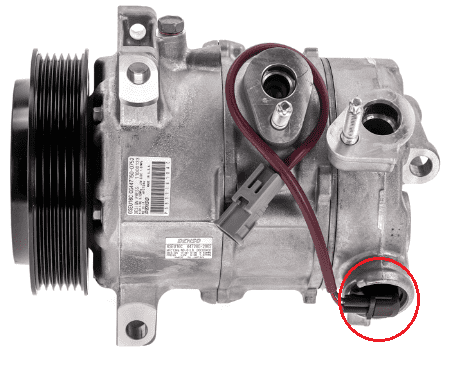

In addition, there are the electronically controlled variable displacement compressor. These use an electronic control valve and control the displacement of the compressor based on a plus width modulation signal supplied by a computer. Please see picture #3.

Gauge readings like the ones encountered above would indicate a restriction in a system, but on some of these systems it would be necessary for there to be an additional problem to get readings like this. Please check back in 2 weeks for information on which systems would have to have an additional problem (and why) and for information on which systems would behave the same as the systems with the fixed displacement compressors.

Leave a Reply