A Sure Sign Of A Restriction (Continued)

By Richard Hawkins

This is a continuation of the blog article published on January 24th. If you have not already read that article, it can be referenced here: https://macsmobileairclimate.org/2023/01/24/a-sure-sign-of-a-restriction/

That article ended with the following: Gauge readings like the ones encountered above would indicate a restriction in a system, but on some of these systems it would be necessary for there to be an additional problem to get readings like this. Please check back in 2 weeks for information on which systems would have to have an additional problem (and why) and for information on which systems would behave the same as the systems with the fixed displacement compressors.

Picking up where we left off, the system that was covered in the previous article utilized a fixed displacement compressor. Here we will be discussing systems using variable displacement and variable output compressors.

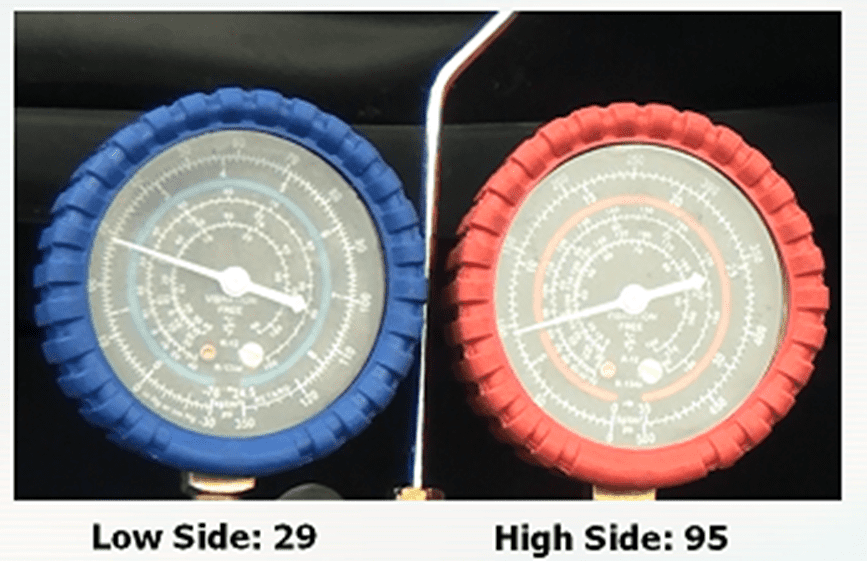

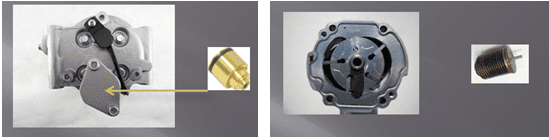

We will first focus on systems using a variable displacement compressor with a mechanical control valve (sometimes also referred to as a pressure control valve). These compressors are designed to try to keep the low side pressure in a range of about 28 PSI to 32 PSI. With a properly operating compressor, when a restriction such as the one in the previous article is encountered, the compressor will pull the low side on down into that 28 PSI to 32 PSI range. Then the action of the control valve will cause the compressor to throttle back to a low displacement. The restriction will allow only a small amount of refrigerant to flow and as a result the high side pressure will be below normal (maybe only 100 PSI to 120 PSI depending on ambient temperature). The liquid level in the evaporator will be very low and the suction line temperature will be elevated and there will be very little cooling taking place. Please see picture #1.

Secondly, systems with variable output scroll and rotary vane compressors will behave very much like the system just described, because they too are designed to keep the low side pressure in a range of about 28PSI to 32 PSI.

For any of these systems to go into a vacuum with a restriction in the system such as the one described with the expansion valve, there would have to be a problem with the control valve which would allow the compressors to operate at full output or at an output which was higher that they should be operating at. Most control valve issues with theses type of compressors tend to cause the compressors to operate at a lower-than-normal output, so situations like this are not encountered very often.

Finally, the most commonly encountered variable displacement compressor nowadays are the electronically controlled variable displacement compressors, so the question needs to be asked: How would a system with one of these compressors behave with a restricted expansion valve such as described above? The answer is: very much like a system with a fixed displacement compressor. The low side would go into a vacuum. This is because the primary input to the computer which is utilized to control the output of these compressors is the temperature of the evaporator. With a restricted expansion valve, the evaporator is not going to get very cold so the computer controlling the compressor is going to be commanding the compressor to full output.

Check back in 2 weeks and we will discuss how a restriction such as this would cause orifice tube systems to behave.

Leave a Reply