Facts to know about the compressor clutch coil

By Richard Hawkins, MACS contributor

Checking the clutch air gap before installing a compressor is an important step in compressor installation. This is because of the possibility of a clutch air gap getting knocked out of adjustment due to rough handling or it being gapped incorrectly at the factory. These issues of course can cause problems with clutch operation. If detected and corrected before compressor installation, a lot of time can be saved.

There are two other “right out of the box” clutch issues that are encountered with some regularity on tech line calls. These are:

1. No clutch function at all. (Usually due to an “open” clutch coil.)

2. The A/C compressor clutch circuit blowing fuses. (Usually due to clutch coil resistance being too low.)

As a result, it is advisable to do some other tests while you have the compressor on the bench checking the clutch air gap.

These tests are:

- Bench testing the clutch to make sure it will function.

- Then checking the resistance of the clutch coil.

Bench testing the clutch for function is easily accomplished. This can be done by simply putting power and ground directly to the clutch coil. This can be done utilizing a battery and test wires or a power probe. If using test wires, an in-line fuse holder with a 10-amp fuse should be utilized for protection and the test wires should be 16 gauge or larger. As soon as power is applied, the clutch should engage. When power is removed, it should immediately disengage. CAUTION: Polarity must be observed when doing this test. If the wires are connected wrong and the clutch coil uses a diode, diode damage will result.

The most common cause of compressor clutch circuit fuses blowing is a compressor clutch coil having a resistance value which is too low. Taking an ohmmeter and checking the clutch coil resistance will quickly tell you the resistance. If your information system provides the resistance value for the specific vehicle you are working on, it is best to use that. However, it does not seem to be readily available for very many vehicles.

Fortunately, the mobile A/C industry provides some guidelines on this. If you search Google for “A/C compressor clutch resistance” there are several articles that come up with clutch coil resistance information. Unfortunately, there isn’t universal agreement on the specifications. Some of the ranges that will be seen are: “2.0 to under 4.5 ohms”, “2.8 to 4.4 ohms”, “around 3.0 to 4.0 ohms”, 3.0 to 5.0 ohms” and then the widest range which is “2.0 to 5.0 ohms”. A short discussion with someone working on a tech line also yielded the answer: “4 ohms plus or minus 1 ohm” (which of course is the range of 3.0 to 5.0 ohms.) (These values are for 12-volt clutches only.)

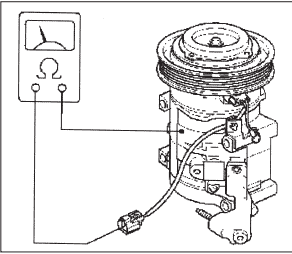

Utilizing all that information, the lowest acceptable resistance value would be 2.0 ohms and the highest acceptable resistance value would be 5.0 ohms. So, two lines could be drawn in the sand there with anything that checked below 2.0 ohms or above 5.0 ohms being disqualified. (Keep in mind that these resistance values are at room temperature. Resistance readings taken at extreme temperatures can be affected. Lower temperatures cause resistance to go down. Higher temperatures cause resistance to go up.) See picture #1.

Picture #1: An ohmmeter test of the clutch coil can tell you if resistance is within an acceptable range. However, be sure you have good connections or the readings on the meter may be misleading. Many clutches have two wires running to them. The one in this picture has one wire and is grounded through the compressor case.

But you might say: That leaves a lot of grey area with all the other ranges that fall within the 2.0 to 5.0 range. How do we address that? Taking all of that into consideration, the “sweet spot” seems to be from about 3.5 to 4.0 ohms, so it becomes something of a judgment call. If you check the clutch coil resistance and it is outside of 3.5 to 4.0 ohms, it would be a good idea to contact the compressor supplier and see what they say.

Some technicians like to go a step further and check the amperage with an in-line amp meter. To determine what the amperage should be, we would use Ohms Law: Amperage = Voltage divided by Ohms. Here is an example using a fully charged battery with 12.65 volts as a power source and a clutch coil with 4.0 ohms of resistance.

12.65 ÷ 4.0 = 3.1625 (So the amperage would be just over 3 amps.)

As was the case with the air gap issues, clutch coil resistance issues and non-functioning clutches are not an everyday thing. However, if you do enough A/C work, it is highly likely you will encounter a non-functioning clutch or clutch coil resistance issue somewhere along the line. As fate might have it, it will probably be on a vehicle where the compressor is buried and removing and re-installing another compressor might take hours. You’ll find taking a few minutes to check clutch function and the clutch coil resistance can prevent this from occurring.

An excellent article on clutch function can be found at the following link: https://www.macsw.org/WEB/images/Macs_Docs/2019TETS/TCCI.PDF

Available in archives to MACS members only. Join MACS as a member to use the members only archives and technical resources. One of the many benefits of MACS membership.

Hi, I have a 2006 Honda Accord 2.4l at first start A/C works find, But when clutch disengage will not reengage till vehicle cools down. checked compressor resistance ohms 4.5 before installing compressor. But over and over again after shutting down vehicle for five minutes clutch will reengage. So I started car again and when compressor clutch disengage, while car still running, removed wire pug in to compressor only one wire checked for resistance ohms where down to 1.3 out of tolerance. should only be 5-2 ohms, nothing over 5 and nothing under 2.

Now my question is how can I correct this hot cold problem with coil

Hello Marvin. I checked and Honda does provide the compressor clutch coil resistance for the vehicle in their service information and it is: “3.9 – 4.3 ohms at 68 °F (20 °C)”

I don’t know what the temperature was when you checked the clutch coil resistance prior to installing the compressor but I’m going venture a guess that it was probably 68F or warmer. With that being the case, it was out of specification to start with and as the temperature increases, the coil resistance should go up.

You stated the following: “So I started car again and when compressor clutch disengage, while car still running, removed wire pug in to compressor only one wire checked for resistance ohms where down to 1.3 out of tolerance. should only be 5-2 ohms, nothing over 5 and nothing under 2.” What was the actual resistance reading when you checked it then?

Regards,

Richard

Hi Richard, just come across your interesting article. What is the reason for coil failure? I have a seiko-seiki compressor on my citroen (PSA group family 2018-2024). For some reason I managed to ruin 2 compressors in a span of a few days. Both have the coil interrupted. I split open first failed coil and I found a a micro thermal fuse inside marked: 221° UM1 44R or 4.4R which has no continuity, bypassing that the coil has continuity. I would be curious to know why this fuse was blown. Another fact to know would be that the AC pressure indicated by a phone app while vehicle running in a fairly hot climate (35°C) was just above 18 bar and was marked in the red if that means anything.

Regards

Hi! Marvin, the solution to the hot and cold problem of the coil is to estsbilize the voltage high enough with a good battery and alternator and replace the clutch relay with a good one!