Refrigerant recovery and system diagnostics

By Richard Hawkins, MACS contributor

This is the sixth in a series of MACS blogs on refrigerant recovery and system diagnostics. You can access the previous blogs here: Part 1, Part 2, Part 3, Part 4.and Part 5.

Last week’s article ended with the following:

Technician: That’s right. Two days later the customer called and said it was cooling terrible. I had him bring it back in and put the gauges on it and checked the vent temperature and it was running about 325 on the high side and about 45 on the low side and the vent temperature was about 55 as I indicated earlier. Of course, the temperature was in the low 90’s that day.

Check back in next week and we will pick back up where we are leaving off with the conversation.

Me: It cooled OK for two days before the problem occurred. Did you happen to ask him what the weather conditions were like during those 2 days?

Technician: He said he had driven “up north”, and it was cool there. When he drove back home, and a “hot spell” moved in that’s when the trouble started. I had him bring it back in and with the pressure readings and vent temperature where they were, I figured I had just messed up and overcharged it when I was in a hurry to get him on the road that day.

Me: Yes, that could have happened, or of course there is always the possibility of a machine getting out of calibration causing an overcharge.

Technician: I didn’t think it was the machine because we had charged several other cars with it since we had done his and those systems had worked fine and the temperature had been in the low 90’s when they were charged. I figured I had just overcharged it.

Me: That wouldn’t have been the first time that has ever happened in this industry and with someone trying to rush you to complete a job, that makes it even more likely to occur.

Technician: For sure. I connected the machine to the car and recovered all the refrigerant. I was careful. The pressure built up some after the machine turned off a couple of times and I turned it back on until all the refrigerant was recovered. Then I charged it back up. I didn’t disconnect anything, and I didn’t pull a vacuum on it because the system had not been opened up and there was no need to open it up.

Me: Tell me more.

Technician: I double checked the specification on the charge to make sure it was 24 ounces. Then I keyed in 24 ounces on the machine and charged the system. The next step was to performance test it and I was expecting it to work perfectly.

It didn’t take long to realize that wasn’t going to happen. The high side climbed right on up into the high 200s fast. When it stabilized, it was acting exactly like it was before I recovered the refrigerant and charged it, which was about 325 on the high side and 45 on the low side.

Me: Just to refresh my memory, that was with an ambient temperature of about 92 and pretty significant humidity. Right?

Technician: Yep.

Me: What happened next?

Technician: Even though I was 99% sure I had done everything correctly, it still seemed to be charge related, so it was time to try charging it with a different machine.

A friend of mine at a different shop has a scale, so I called and made arrangements to borrow his scale. I went over and got his scale, brought it back to the shop here and recovered the refrigerant again. Then I disconnected the machine, connected his scale and CAREFULLY charged it with 24 ounces, crossed my fingers, fired it up and tested the A/C system. Then I was ready to take a bomb and blow it up.

It was still acting the same way. I was starting to wonder if somehow a restriction had developed somewhere in the system. It was late in the afternoon, and I’d had enough of it for the day so I just left it there in the bay and walked away and went fishing when I got home from work to get my mind off of it.

Me: Both using that scale and walking away and going fishing were good ideas. Sometimes the best thing to do when you run in to one like this is to just walk away to get your head cleared. So that was yesterday afternoon and things are essentially at the same place now as when you left it yesterday afternoon, right?

Technician: Yes. Any thoughts on what the next step needs to be?

Me: First a question: Does your recovery/ recycling/ recharge machine tell you how much refrigerant is removed from a system when you do a recovery?

Technician: No, it doesn’t.

Me: My thoughts are that this system has an overcharge of refrigerant in it, as you originally thought.

Technician: No disrespect to you, but that seems almost impossible as careful as I have been and as many times as I have charged this system now.

Me: I’m with you. I understand how you would think that was the case. Now there is something I need for you to do to help confirm my thoughts.

Technician: Sure, what is that?

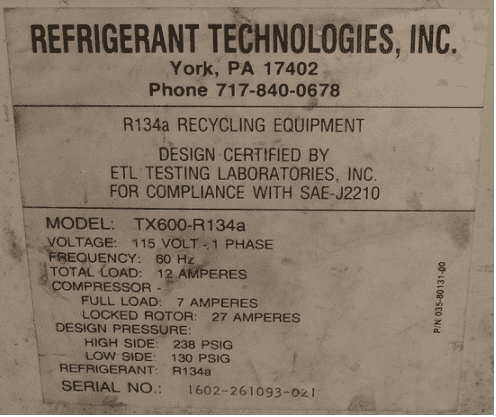

Me: There is a data plate located somewhere on that R/R/R machine, probably on the back. Can you take a look at the data plate and see if you see a reference to an SAE standard. You should see a reference to J2210.

Technician: OK let me take a look. (A minute or so later.) Yep, it has J2210 on it. What does that mean?

Me: It is a standard that was adopted for older R/R/R machines. That machine does not have the capability of removing all the refrigerant from that system. So without the system being opened up for refrigerant to boil off or a deep vacuum being pulled on it long enough to remove all of the refrigerant, that makes it very likely you do indeed have a refrigerant overcharge condition there.

Technician: What is your suggestion on the next step?

Me: Do you have a refrigerant identifier? I ask because I want to be sure that the refrigerant is not contaminated, even though there is a very slim chance of that being the case.

Technician: No, I don’t.

Me: Can you check with your friend you borrowed the scale from and see if he has an identifier and also check with him and see if he has a R/R/R machine that says J2788 on the data plate. Once you find out, can you let me know and we can discuss the next step.

Technician: Sure, I’ll do that.

This was a lengthy tech call and had some interesting twists to it. Check back in next week and we will continue with refrigerant recovery and system diagnostics.

The most valuable and diverse mobile A/C training will be available at MACS 2023 Training Event and Trade Show, February 2-4, at the Gaylord Opryland Resort and Convention Center in Nashville, TN. Check it out, we would love to see you there!

Leave a Reply