The pressure readings

By Richard Hawkins, MACS contributor

Sometimes when confronted with a challenging problem with an A/C system, the pressure readings might not seem to conform to the way the system is performing. Also, pressure readings might indicate that a component needed to be replaced and after replacement the system did not perform any differently.

When encountering these situations, are you taking time to determine the precise location in the system where the pressure readings are being taken? If you are among the top A/C technicians at MACS members shops, your answer to this question would likely be YES. However, based on the experience of years of tech calls with other technicians who were encountering such A/C issues, the answer all too often is NO.

Why is this such an important piece of diagnostic information? Because what you are seeing on your gauges may not be what the TRUE pressure readings are at the compressor and that can result in an incorrect diagnosis and a lot of frustration. Consider that the further a service port is located from the compressor, the greater the possibility that pressure readings being displayed on a gauge can be different from the TRUE pressure reading at the compressor.

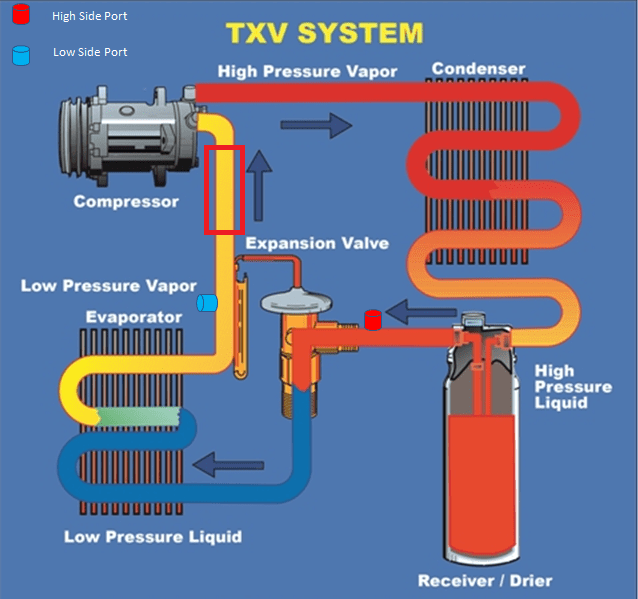

That is because it is possible to have restrictions in a number of places in an A/C system. For example, let’s say that you are dealing with an expansion valve system that has the high-pressure service port located on the liquid line, just ahead of the expansion valve. A restriction could exist in the liquid line, drier, condenser or discharge line that could affect the reading on the gauge. See pictures #1 and #2.

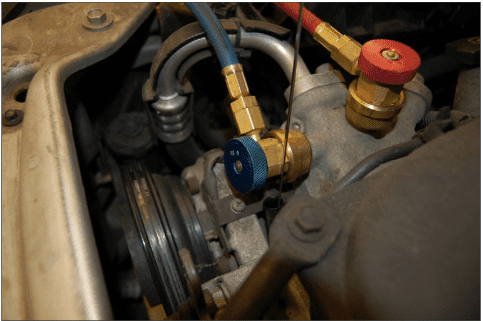

Picture #1: Having the service ports located right at the compressor, such as on this manifold, ensures being able to get the actual pressure readings the compressor is producing (unless there is a problem with a Schrader valve, hose connector, gauge or hose connected to the gauge).

Picture #2: With the high pressure service port so far away from the compressor, a restriction anywhere between that service port and compressor could have a big effect on the pressure that is being read on the gauge verses what the TRUE high side pressure is at the compressor.

The location of the service port on the low side can also result in the TRUE low side pressure at the compressor not being displayed on a gauge. See picture #3.

Picture #3: A restriction in the suction line between where the low side service port is located (where the red rectangle is) and the compressor could result in the TRUE low side pressure at the compressor not being displayed on the gauge.

For more information on this, please refer to the January 2022 MACS Service Report. There is a link in the Service Report to a webinar we conducted on this subject and also a diagnostic situation/case study I personally encountered a number of years ago. The diagnostic situation/ case study begins toward the bottom of page 4 of the Service Report.

MACS Service Reports are a MACS member-only benefit. Eight annual issues detail an in-depth service and repair issue. Join MACS today and take advantage of these great educational benefits!

MACS 2023 Training Event and Trade Show will take place February 2-4, 2023 in Nashville, TN. Learn more at this link.

Leave a Reply