Too Many Compressors

The blog article published on November 8, 2022, focused on understanding the importance of knowing the precise location of service ports when faced with a challenging A/C diagnostic issue. It went on to further explain applying this information to diagnostics. That article can be referenced here: The Pressure Readings

In the article there was a link to the January 2022 MACS Service Report. It can be referenced here: MACS Service Report ** In the Service Report, a diagnostic situation/ case study which I encountered several years ago was covered. It begins toward the bottom of page 4 of the Service Report. It involved a visit to a shop and led off with an interesting greeting I received when first arriving there. It began with a somewhat hostile, “How come you guys have so many problems with your compressors?”

It was an indication of frustration on the part of the owner (who was also the technician who was working on the vehicle). He was laying blame for an A/C performance problem on the compressor currently installed on the vehicle he was working on and some additional units that had also been installed on it. There had been four different compressors on that system and the pressure readings and system performance had been pretty much the same with each one. Despite this, he wanted to install another compressor and was upset that the warehouse manager was holding back on sending it out.

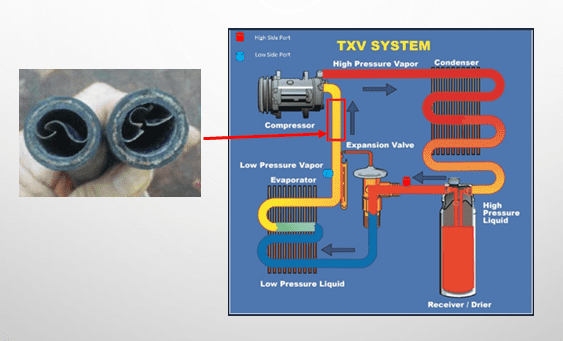

After quite a bit of discussion, I was able to convince him that he did not have a compressor problem. However, this is an illustration of what all too many inexperienced A/C technician’s favorite diagnostic tool is: Let’s install a new compressor and see if that fixes the problem. In this case the problem ended up being a collapsed suction hose. See picture #1.

Collapsed suction hoses are something that are not encountered that often and the initial pressure readings did point toward a compressor issue. But after that compressor was replaced and the pressure readings and system performance were the same, that should have been an indication that the compressor was not the problem. Instead, there were two additional compressors installed with the same results.

Based on experience on tech line calls, this happens all too often. Some common reasons that multiple compressors are often installed unnecessarily are as follows:

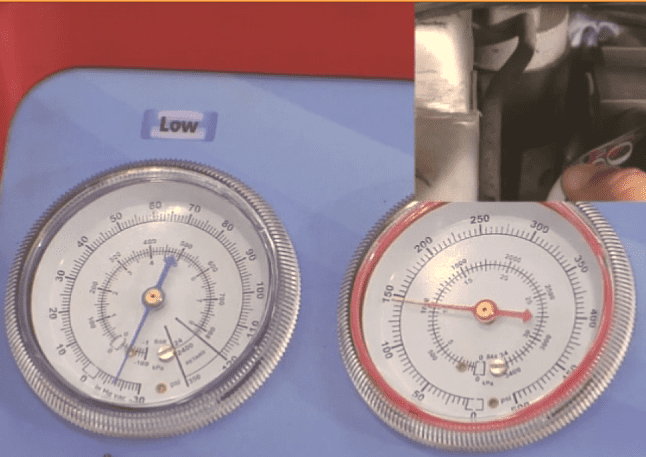

1. With the system running, the low side gauge is indicating a vacuum. For some reason a lot of inexperienced technicians see this as a sign of a bad compressor. It is actually an indication of a restriction in the system. See picture #2.

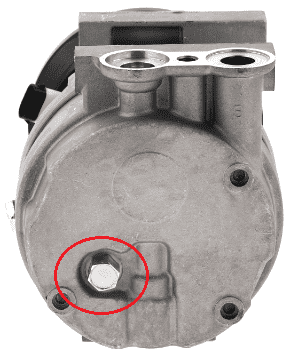

2. The high-pressure relief valve (HPRV) is releasing refrigerant. Inexperienced technicians somehow often think this is a sign of a bad compressor and will replace a compressor because of it. It of course a sign of too much pressure in the system. See picture #3.

These are things that experienced technicians are aware of, but less experienced technicians are not. Many compressor companies report many NTF (No Trouble Found) compressors when conducting warranty analysis on returned units. A large percentage of them are a result of the reasons outlined above. This not only costs compressor companies, but also the distributors who supply the units and the shops who are installing them. Utilizing a bit more caution when initially replacing a compressor and when deciding to replace a compressor that has already been replaced with no resulting change in system operation can benefit all involved in the industry.

**MACS Service Reports are a MACS member-only benefit. Eight annual issues detail an in-depth service and repair issue. Join MACS today and take advantage of these great educational benefits!

Leave a Reply