Avoiding Expansion Valve Woes (Part 3)

By Richard Hawkins, MACS Technical Correspondent

This is part 3 in a series of articles about avoiding expansion valves woes. If you have not already read the previous two articles, they can be found here:

Avoiding Expansion Valve Woes (Part 1)

Avoiding Expansion Valve Woes (Part 2)

Picking up where we left off

The earlier article ended with the following: Unfortunately, we have run out of space. Check back in two weeks and we will address those possibilities and cover the second category of expansion valve tech calls which was referenced in the first article.

Roger: OK and what would those possibilities be?

Me:

1. That would include an issue with the evaporator temperature sensor not being placed properly where it would sense the temperature correctly. That would most likely only occur if someone had been doing some work in that area.

2. A problem with the computer could be the cause, although that is not high on the list of probable causes.

3. A sticking clutch relay would be the most likely cause and not only would that prevent the compressor from cycling, but the A/C would be running all the time, even when turned off.

4. If there was no clutch gap and the clutch hub was positioned where it was in tight contact with the pulley, then that would cause the compressor to run all the time. However, that would only occur on a compressor that had just been installed where the clutch was not gapped. That could be ruled out here because the compressor has not been changed and the system had previously been functioning properly.

Roger: OK. I’ll check those things out. Thanks for the call and the information. Also, I won’t be changing any more expansion valves trying the fix evaporator freeze-up problems.

Summary

At the beginning of the first article, I mentioned a second category of tech call also involved expansion valves. Those calls involved brand new valves that were bad right out of the box. It is not supposed to happen, but sometimes it does and when it does, it seems like it is on one of those vehicles where the expansion is buried inside the dash and hours are involved doing an R&R.

I would receive a message to call someone who had installed a new expansion valve and the low side was going into a vacuum. This of course is a definite sign of a restriction in a system. There usually seems to be about an 80% chance it is expansion valve related, 15% chance it is drier related and 5% chance it is something else. After doing temperature testing to make sure there was not a restriction somewhere else, they would replace the expansion valve that would fix the problem.

What was going on? Most likely the diaphragm in the expansion valve was not charged (with refrigerant) properly at the factory or it had lost its charge and the valve would not open. As a result, the low side was going down into a vacuum.

I know of several top notch A/C shops who utilize a procedure to avoid this. The first order of business in these shops when an expansion valve is taken out of the box (just before installation) is for the technician to see if they can blow through the inlet of the valve with their mouth. If they cannot, then the valve is put back in the box and labeled as defective and it is returned for credit.

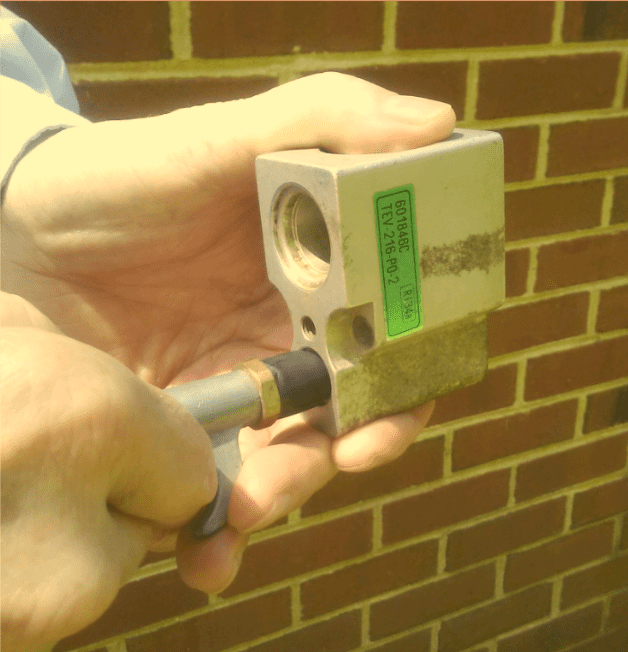

While we cannot recommend this test for health reasons, a good test can be conducted by taking a rubber tipped blow gun and trying to blow low pressure shop air through the valve. If you cannot blow through it, then there is a problem because it should allow a free flow of air. Please see the picture below.

We hope this series of articles have been interesting, useful and helpful with avoiding expansion valve woes.

See you next time!

Leave a Reply