Staying RRR current

By Richard Hawkins, MACS contributor

This is the seventh in a series of MACS blogs on refrigerant recovery and system diagnostics. This time we’ll discuss the importance of staying RRR current. You can access the previous blogs here: Part 1, Part 2, Part 3, Part 4. Part 5

and Part 6.

Last week’s article ended with the following:

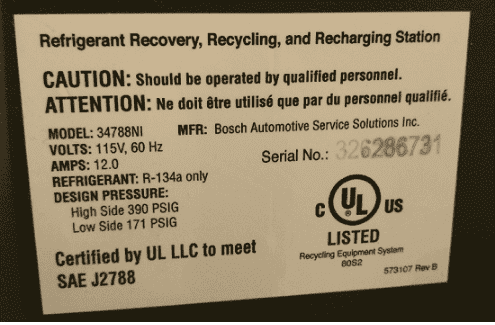

Me: Can you check with your friend you borrowed the scale from and see if he has an identifier and also check with him and see if he has a R/R/R machine that says J2788 on the data plate. Once you find out, can you let me know and we can discuss the next step.

Technician: Sure, I’ll do that.

Continuing:

Me: Thanks. If they have them, can you see if they would be OK with you taking this car over to their shop and testing the refrigerant and if it checks out pure, then recovering it with their machine.

Technician: OK. I’ll let you know shortly.

He contacted me about fifteen minutes later and the conversation went something like this:

Technician: I called the other shop, and they have a refrigerant identifier and the J2788 machine. They said to come on over, I was welcome to use their equipment. I’m headed over there now.

Me: Great. I’m going to speculate that the refrigerant is going to check out as being pure. If not, please give me a call. If it is pure, then go ahead and recover it with their machine and be sure to write down the amount you recover, then call me.

Technician: OK. Sounds like a plan.

About an hour or so later he called me, and the conversation went something like this:

Technician: The refrigerant checked out fine. No contamination with other refrigerants and no air contamination. Their machine pulled 30 ounces out of that system.

Me: Great. The problem has been found. With a 24 ounces charge specification that system was overcharged by 6 ounces which is a 25% overcharge. If you take that same R/R/R machine and charge it with 24 ounces, the A/C system should work perfectly. Please call me and let me know how it’s doing after you charge it and test it.

He called me about 30 minutes later and the conversation continued:

Technician: I got it charged and tested it and it’s cooling great. It’s running about 215 on the high side and about 30 on the low side and blowing about 42 degrees out of the vents.

Me: What’s the ambient temperature and humidity there?

Technician: It’s about 91 here and we have a pretty good “dose” of humidity.

Me: Congratulations. Sounds like you have it fixed.

Technician: Yea, finally. It’s a good feeling. Do you think there is something wrong with the machine back at our shop?

Me: It’s possible, but I doubt it. I’ve read about a few recovery tests conducted on the older J2210 machines, talked to a guy that did some testing and actually did a test on a J2210 machine myself. It isn’t unusual for them to leave 20% to 30% of the refrigerant in a system after a recovery.

Technician: Do you happen to recall the results on the test you did?

Me: Yes, I do. It was on a Crown Vic with a 27-ounce refrigerant capacity. A J2788 machine pulled 9 ounces out after we did a “complete” recovery with the J2210 machine. That machine had left 33% (a third) of the refrigerant in the system. I remember it well because we did a video on it.

Technician: I’ve only worked at this shop for about 4 months, but I have used our machine on a number of other A/C jobs and haven’t had any problems. Why do you suppose I only had a problem with this car?

Me: Well, you didn’t have a problem with this car until the hose was changed. This machine was used on it initially when you changed the compressor and the system worked fine and that was with the ambient temperature in the low 90s. The difference is that when you changed the compressor, a lot of time elapsed between the time the recovery was completed and when the system was charged.

You also likely pulled a deep vacuum on it for much longer than the 5 to 10 minutes that was done when the hose was changed. That insured that there was no residual refrigerant in the system at the time it was initially charged. That wasn’t the case with the hose being changed and the subsequent recoveries and charges that occurred.

Technician: OK. I see what you mean. Sounds like the boss should investigate getting a newer machine.

Me: If the machine in your shop had been a J2788 unit then this problem would never have occurred. Also, the J2788 machines charge much more accurately. The charge accuracy on them is plus or minus 1/2 ounce. There are advantages to having a newer machine.

In the meantime, you will likely be using the existing machine until it is replaced, or you may be using it for a long time if he decides not to replace it. In either case just remember the shortcomings that it has regarding refrigerant recovery and tell the other guys in the shop so that another situation like you had with this car can be avoided.

Technician: For sure. Thanks for the help. This is one that I’ll remember for a long time.

Mobile A/C training is a marathon not a sprint we continue to learn with every repair. Consider attending MACS 2023 Training Event and Trade Show where you’ll have the opportunity to attend 41 hours of mobile A/C training from 31 expert instructors. Hotel reservations must be made by January 9, 2023 at the Gaylord Opryland Resort and Convention Center.

Leave a Reply